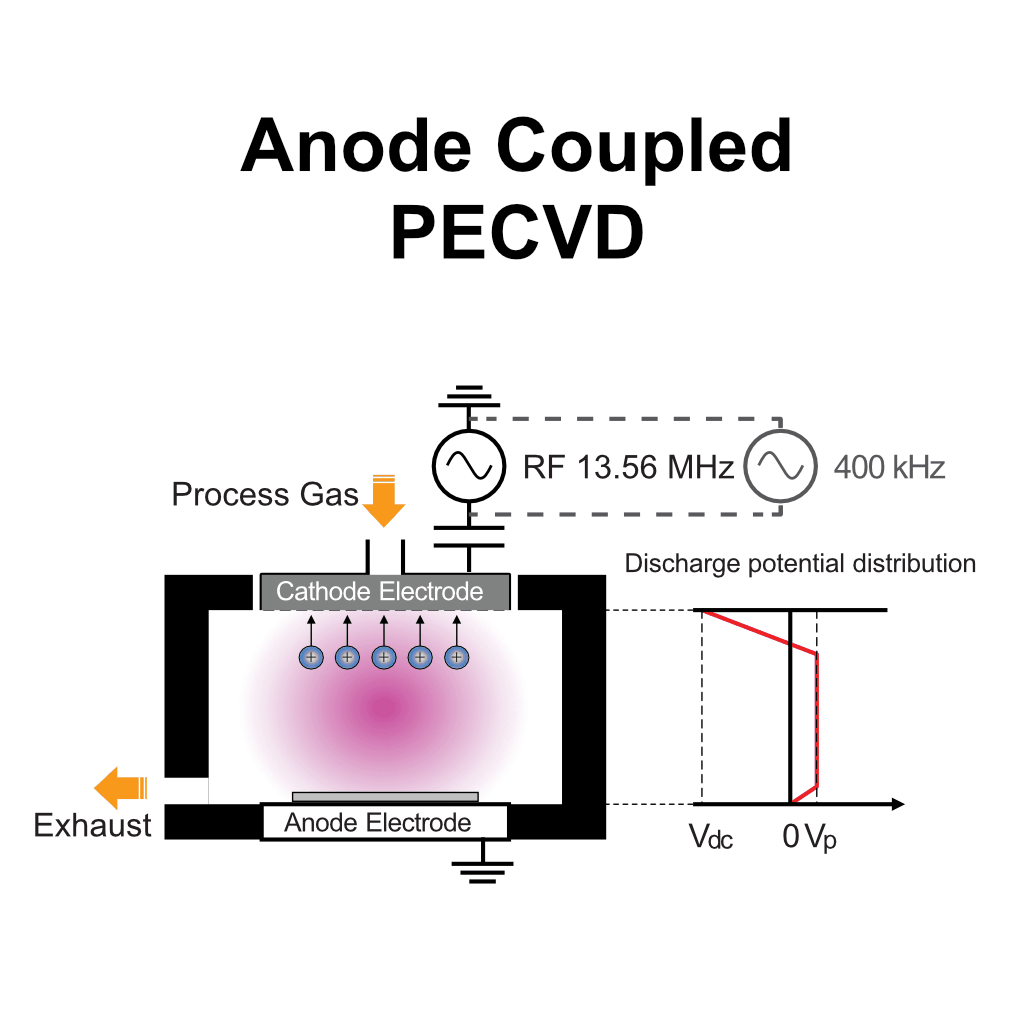

Plasma Enhanced Chemical Vapor Deposition (PECVD) is a highly efficient method for depositing thin films by introducing reactive gases into a plasma state. This process generates active radicals and ions, facilitating chemical reactions on the target substrate to form the desired film. A key advantage of PECVD is its ability to operate at lower temperatures compared to thermal CVD, making it suitable for temperature-sensitive applications.

Anode PECVD is widely used in semiconductor manufacturing to deposit silicon nitride (SiN) as a passivation layer and silicon oxide (SiO₂) as an interlayer insulating film. These films are integral to the fabrication of both compound and silicon-based semiconductors, providing reliable performance and enhanced device stability in a variety of applications.

SiH4-SiNx deposition

SiH4-SiNx deposition using Samco’s Anode-Coupled PECVD systems provides a reliable solution for forming silicon nitride films with excellent uniformity, low stress, and high optical quality. This process supports a wide range of applications, including dielectric layers, passivation films, and hard masks in device fabrication.

With precise control over deposition parameters, SiH4-SiNx films can achieve tailored properties such as high mechanical strength, low leakage current, and optimal refractive indices. The process is ideal for both R&D and production environments, delivering stable, reproducible results across diverse applications.

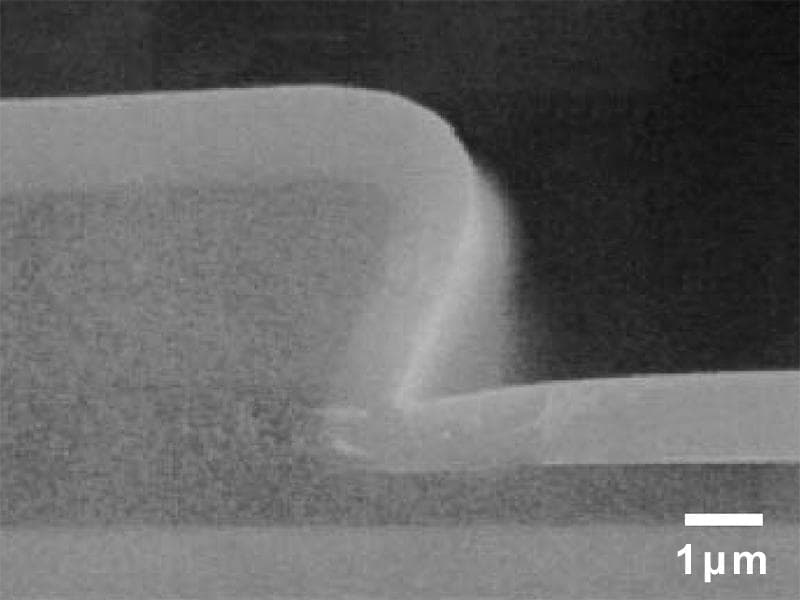

Excellent step coverage is achieved in SiN deposition as a passivation film for reverse mesa shapes.

Products

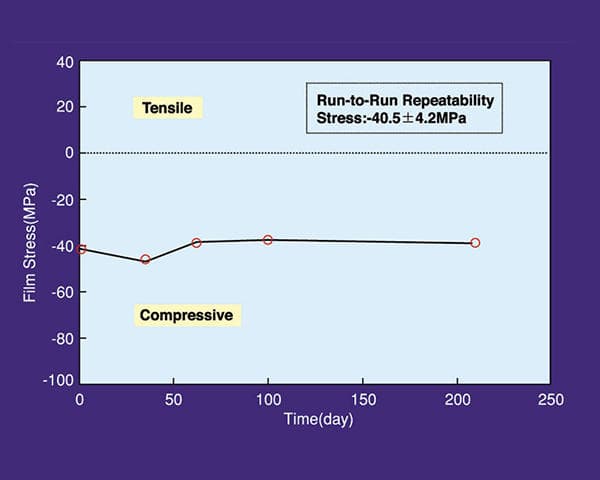

Stable film formation, with no change in stress over extended periods.

Products

Linear control of film stress, with no stress change after annealing and a wide process window.