⌀240 mm

Cassette Loading

none

Carrier Tray Transfer

Production system with dual cassettes

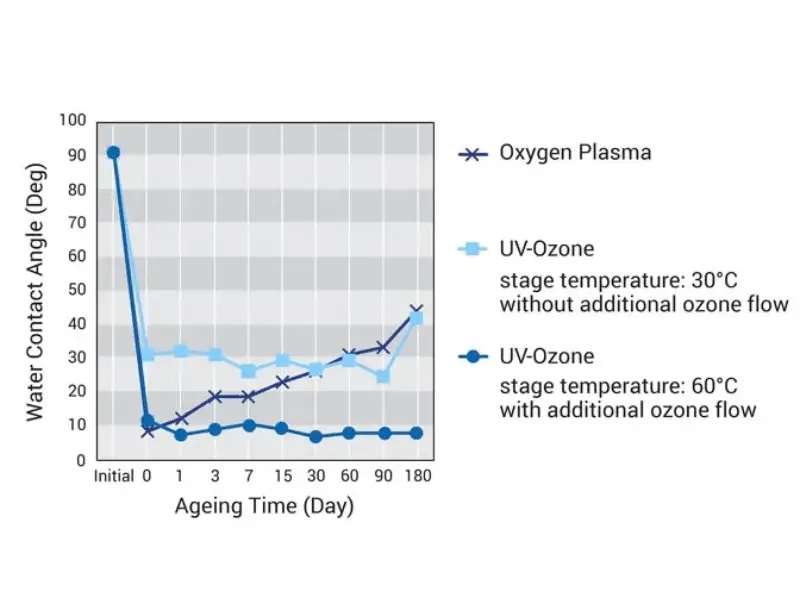

The UV-300HC is a high performance and cassette loading UV ozone cleaner for production. This industry-leading system has 2 loading cassettes and can achieve high ashing rates of 200-300 nm / min. This system uses a unique combination of ultraviolet irradiation, high concentration of ozone, and controlled stage heating to gently, yet effectively, remove organic materials from a variety of substrates, including silicon, glass, compound semiconductors (GaN, SiC, GaAs, and InP), sapphire, ceramics, etc.

Key Features & Benefits

- Processing up to ø240 mm (ø3″ x 5, ø4″ x 3, ø8″ x 1)

- High ashing rates of 200 – 300 nm/min

- Heating stage accelerates the cleaning rates and realizes a broad process temperature range

- Gap adjustment between the stage and the quartz diffusion plate enables uniformity improvement over the substrate

- Compact, uses minimum cleanroom space

- Easy, operates at atmospheric pressure – no vacuum system required

- Soft, completely dry process will not cause electrical damage to substrates

- Built-in ozone catalyst unit for reducing ozone concentration in the exhaust to a safe level

- Built to UL standards

Applications

- Surface cleaning of plastic packages and lead-frames

- Surface cleaning of compound semiconductor (GaN, SiC, GaAs, and InP)

- Surface modification (wettability and adhesion improvement)

- Surface oxidation (thin oxidized layer deposition)

- Photoresist ashing, stripping, and descuming

- Removal of organic contaminants

- UV curing