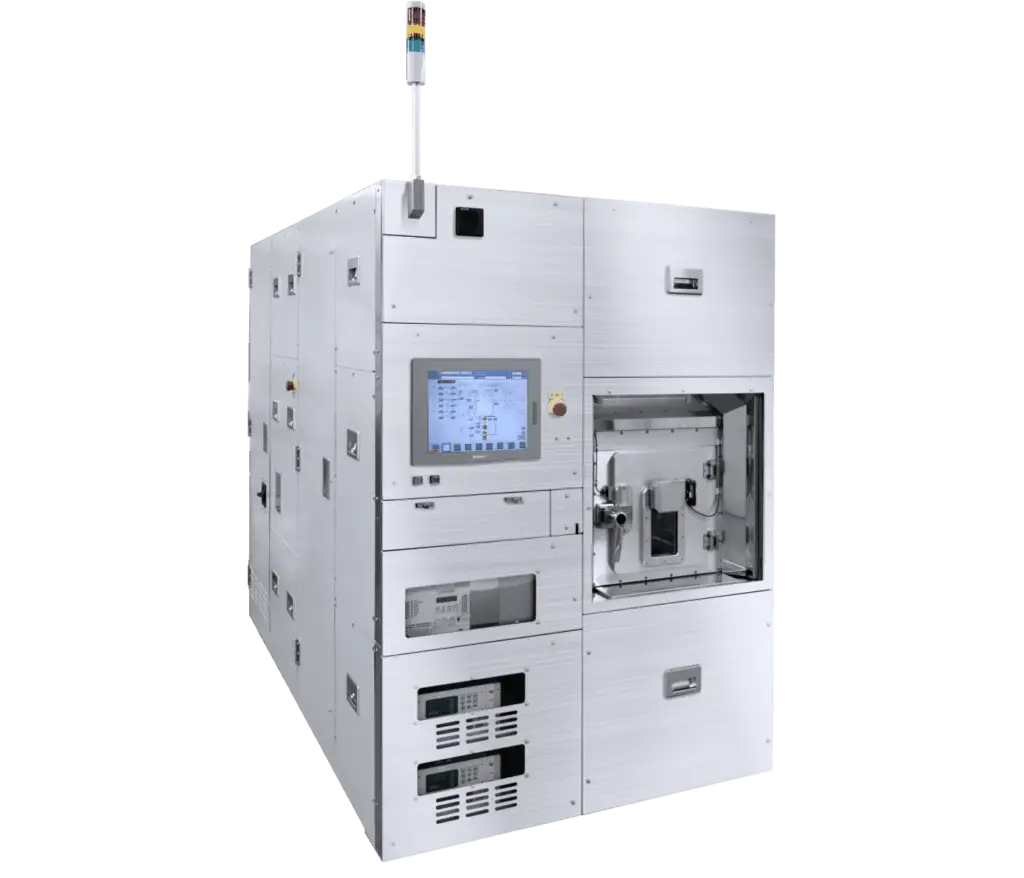

Dual chamber system

The RIE-802BCT is a silicon deep drilling system for mass production with two reaction chambers that employ inductively coupled plasma as the discharge form.

An air cassette and wafer edge protection ring are standard, as well as a high-precision wafer aligner.

This high performance system is capable of high aspect ratio processing (over 100) and low scallop processing while maintaining a high etching rate and resist selection ratio.

Key Features & Benefits

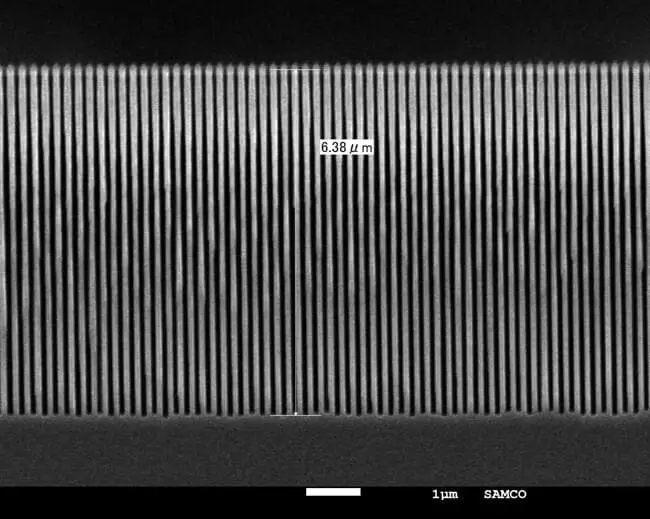

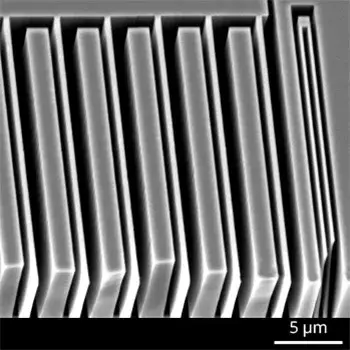

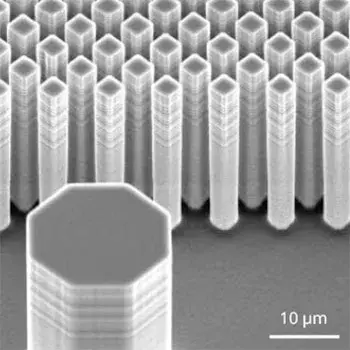

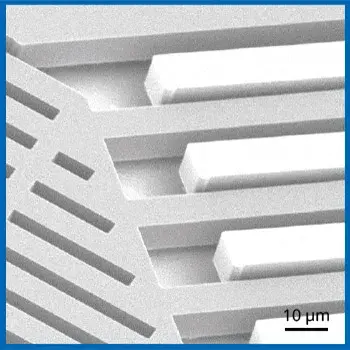

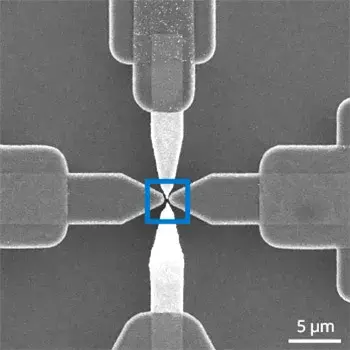

High aspect ratio processing

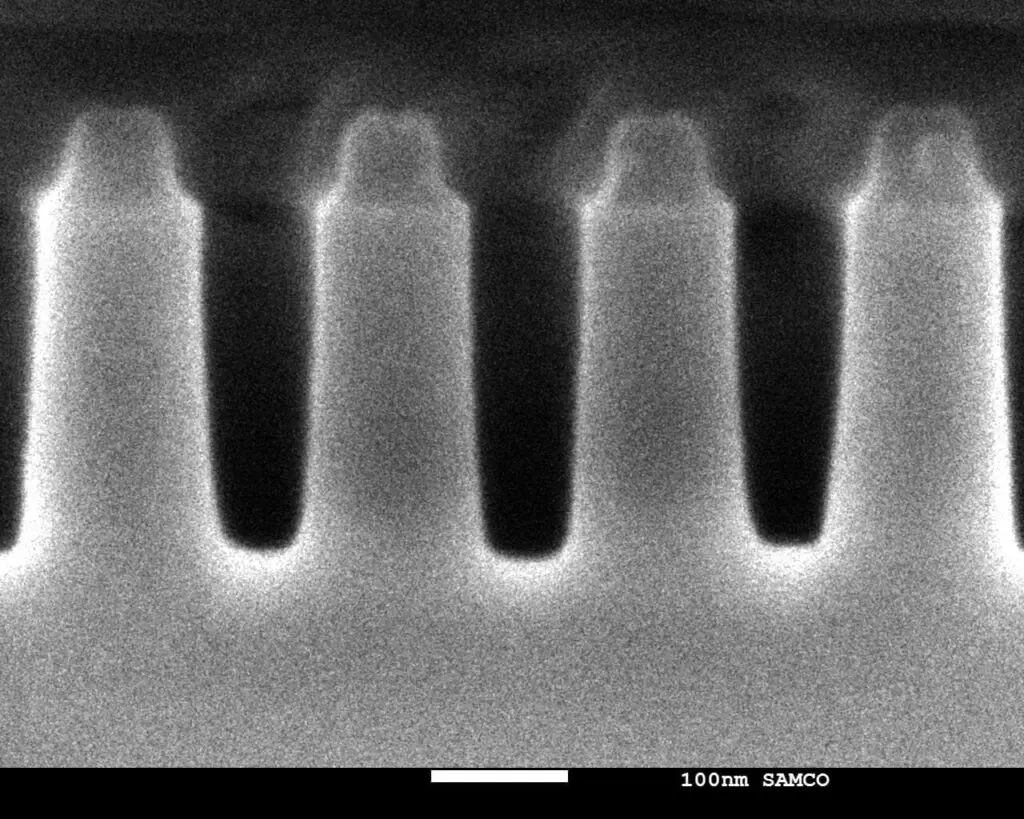

The unique plasma generator and reactor structure enables high aspect ratio processing while maintaining a vertical etching shape.Low scallop processing

By switching the gas at high speed, the scallop can be reduced while maintaining the etching rate.In 2003, Samco was the first Japanese equipment manufacturer to obtain a license for the Bosch process. Since then, the process library we have built up enables us to process various shapes and materials.

Applications

- Fabrication of MEMS (acceleration sensors, gyro sensors, pressure sensors, actuators, etc.)

- Inkjet printer head processing

- Formation of through silicon via (TSV)

- Production of power devices (super junction MOSFET)

- Plasma dicing