⌀300 mm

Open Load

none

none

Processing up to ø300 mm (ø12")

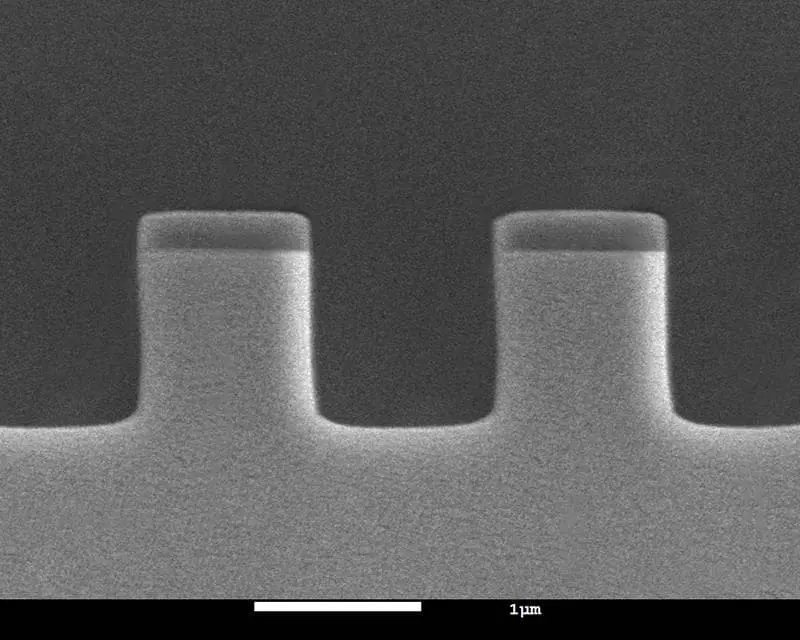

The RIE-300NR is an ideal reactive ion etching system for processing of ø300 mm wafer and multiple wafers (ø3″ x 12, ø4″ x 8, etc.) with excellent uniformity. This system is designed to minimize factory space requirements, enhance throughput, maximize uptime, and reduce the cost of ownership through reliable hardware and ease of service.

Key Features & Benefits

- Processing capabilities include:

- ø3″ x 12

- ø4″ x 8

- ø12″ x 1

- User-friendly touch screen interface

- Fully automatic “one-button” operation with full manual override

- An optimized shower head to deliver process gas uniformity

- A close coupled gas delivery box which reduces the residence time

- A symmetrical evacuation design coupled to a TMP creates an efficient flow

- Automatic pressure control that allows for precise control of process pressure independent of gas flow

- Dry pump and system layout allow for ease of maintenance

Applications

- Removal of interlayer films for failure analysis of ø300 mm

- Etching of Si, SiO2, SiN and Poly-Si

- Etching of resins and desmear

- Photoresist ashing, stripping, and descuming

- Surface modification (wettability and adhesion improvement)