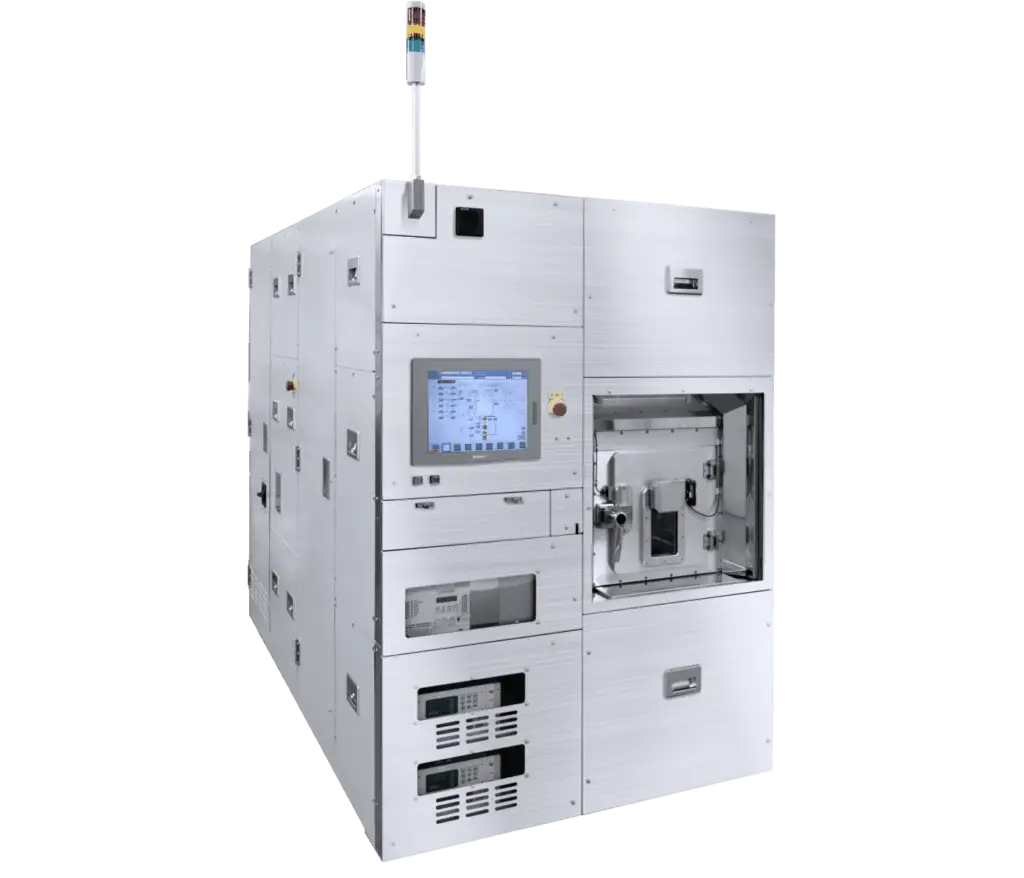

⌀8″

Load Lock

HSTC™

none

Excellent repeatability & stability

The RIE-800iP, a load lock ICP-RIE plasma etching system, utilizes high-density inductively coupled plasma (ICP) to achieve precise etching. Designed for wafers up to 200 mm (8 inch), the system features an advanced ICP source, temperature-controlled electrode, and a high-flow exhaust system, all within a compact, space-saving design. This system provides reliable and exceptional process control, ensuring excellent efficiency for a wide range of etching applications, including GaN, GaAs, InP, SiC, and various other materials.

Key Features & Benefits

- New ICP Source “HSTC™: Hyper Symmetrical Tornado Coil

High RF power (2 kW or more) can be applied efficiently and stably, and good uniformity is achieved. - High Flow Exhaust System

The exhaust system directly connected to the reaction chamber enables a wide range of process windows from small flow and low pressure ranges to large flow and high pressure ranges. - Lower Electrode Lifting Mechanism

The distance between the wafer and the plasma is optimized to ensure good in-plane uniformity. - Easy-maintenance design

The TMP (turbomolecular pump) are integrated into the unit for easy replacement.

Applications

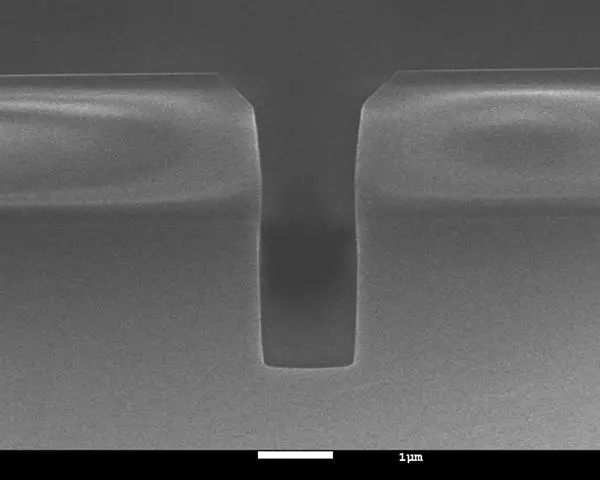

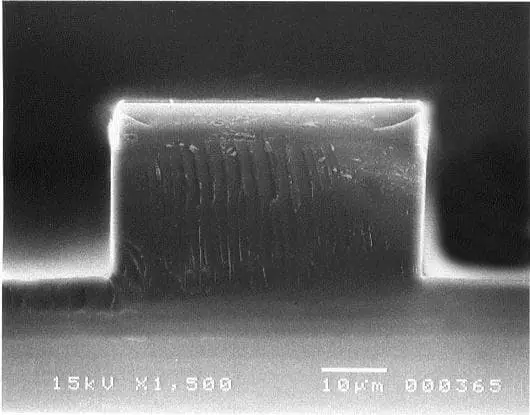

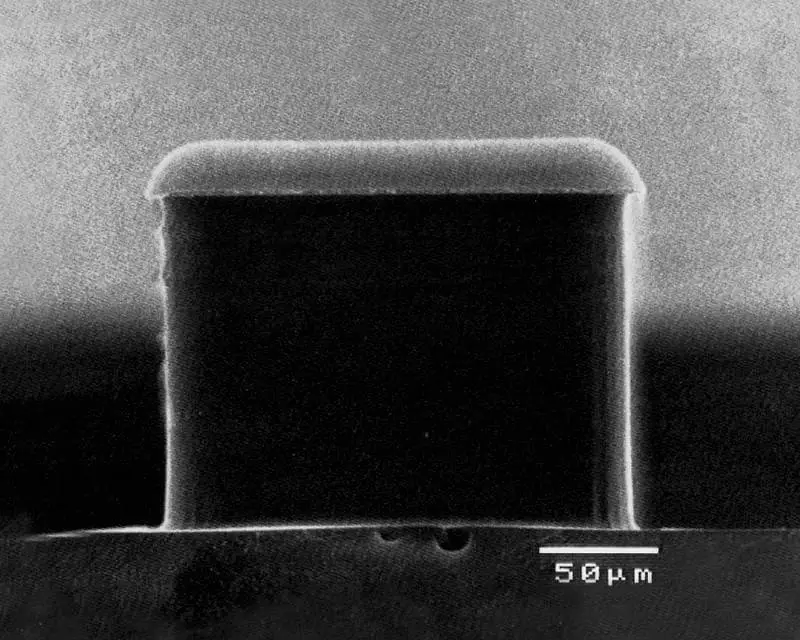

- High-precision processing of compound semiconductors such as GaN, GaAs, InP, etc.

- High-speed processing of SiC and SiO₂

- Etching of ferroelectrics (PZT, BST, SBT, SBT), electrode materials (Pt, Au, Ru, Al) and other difficult-to-etch materials

- Plasma dicing and thinning of compound semiconductor wafers