⌀220 mm

Cassette Loading

LSCVD®

Carrier Tray Transfer

Batch processing for small diameter wafers

The PD-270STLC is a low-temperature (80 ~ 400°C), high-rate (>300 nm/min) plasma-enhanced CVD system for mass production. Samco’s unique liquid source CVD system uses self-bias deposition techniques and a liquid TEOS source to deposit SiO2 films with low stress, from thin films to extremely thick films (up to 100 µm). This system achieves high throughput by employing atmospheric cassette loading and ø236 mm carrier tray, which enables to install three ø4 inch wafers.

Key Features & Benefits

- Processing up to ø236 mm carrier tray (ø3″ x 5, ø4″ x 3, ø8″ x 1)

- Cathode coupled self-bias deposition techniques enables the high rate (>300 nm/min) deposition of low-stress films

- By low temperatures deposition, films can be deposited on top of plastic surfaces

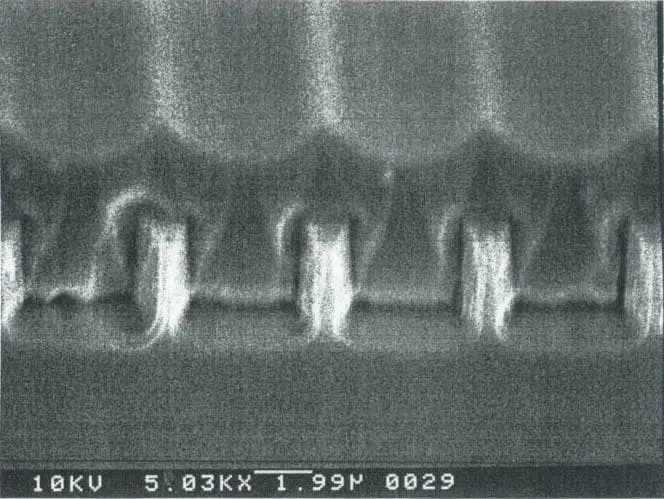

- Excellent step-coverage of high aspect ratio structures

- Control of refractive index by using germanium, phosphorus, and boron liquid source

- Excellent process uniformity and repeatability

Applications

- Deposition of protective films over plastic materials

- Deposition of the insulating film on via sidewalls for 3D LSIs

- Fabrication of optical waveguides (fiber core/cladding)

- Fabrication of masks for use in the production of micromachines

- Coverage of high aspect ratio structures such as MEMS devices

- Temperature compensation film and passivation film for SAW devices