Open load system for R&D

The Samco AL-10 is a highly versatile open-load thermal ALD tool for R&D applications. This system is the result of Samco’s ALD technology development since the 80s. Multiple gas lines and liquid sources offer a wide range of material processing capability for various research fields including next-generation power devices and nano-electronics.

AL-10 achieves precise film thickness control and good step coverage by alternatively supplying organometallic precursors and oxidants/nitrogen containing gases to the reaction chamber for the deposition of oxides and nitride compounds. It can process up to three ø4-inch wafers simultaneously.

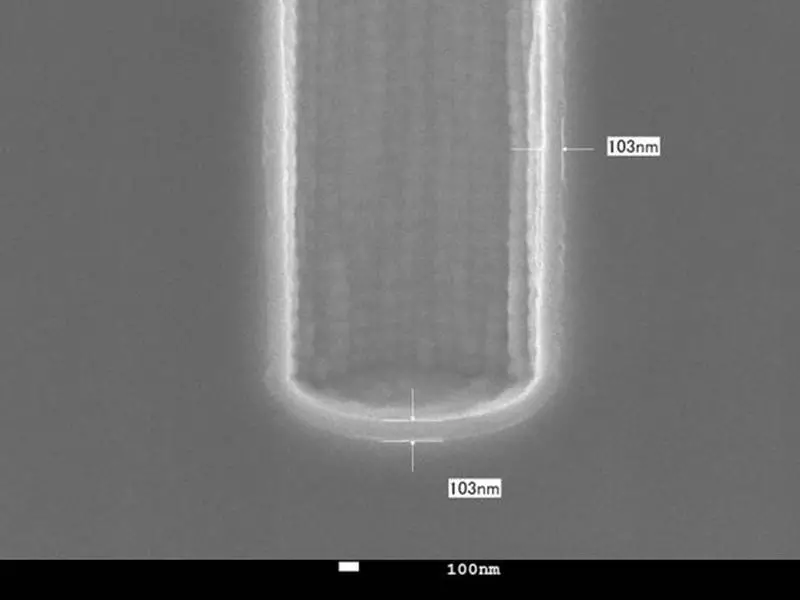

The substrate heater operates at temperatures up to 500°C, and the system supports high-speed gas switching. These features allow for deposition of high-quality films with excellent uniformity and repeatability. Depositing one atomic layer at a time allows for precise control of the film thickness down to the angstrom level. Step coverage is extremely good even on high-aspect trenches and hole structures. For AlOₓ film deposition, coverage of trench patterns with an aspect ratio higher than 40 have been demonstrated with dielectric strength of 7.5 MV/cm.

Additionally, the system is designed to minimize precursor consumption, offering a low cost of ownership. Its design also emphasizes ease of maintenance, ensuring reliable and efficient operation.

Key Features & Benefits

- Capable of handling up to one 200 mm wafer or multiple smaller wafers/pieces with a 230 mm processing tray.

- Advanced Reaction Chamber Design:

Separate precursor inlet lines and process gas lines minimizes particle generation that allows for pin-hole free film deposition. - Enhanced Efficiency:

Pulses of tens of milliseconds reduce precursor loss and improve deposition efficiency. - Robust Safety Features:

Equipped with various interlocks and anomaly detection functions for safe operation. - Up to four liquid precursors and six process gas lines.

- Heated chamber wall to prevent deposition of reaction byproducts to allow for uniform substrate temperature distribution and ease of maintenance.

Applications

- Gate oxide films and passivation films for next-generation power devices

- Uniform coatings on 3D structures such as MEMS

- Anti-reflective coatings for high power laser

- Passivation film of carbon nanotubes

Options

- Additional plasma unit (13.56 MHz)

- Glove box interface

Papers

Paper 1:

Shoufa Liu, Xun Qiao, Yinwei Wang, Huan Xie, Ning Zhang, Dancheng Liu, “Magnetic and optical behaviors of SnO2-x thin films with oxygen vacancies prepared by atomic layer deposition”, Ceramics International, Volume 45, Issue 3, 2019, Pages 4128-4132, ISSN 0272-8842

https://www.sciencedirect.com/science/article/abs/pii/S0272884218331389

Paper 2:

Noriharu Takada, Noriyuki Taoka, Akio Ohta, Taishi Yamamoto, Nguyen Xuan Truyen, Hisashi Yamada, Tokio Takahashi, Mitsuhisa Ikeda, Katsunori Makihara, Mitsuaki Shimizu, and Seiichi Miyazaki. “Comparative study of photoluminescence properties obtained from SiO2/GaN and Al2O3/GaN structures.” Japanese Journal of Applied Physics 58.SI (2019): SIIB22.

https://iopscience.iop.org/article/10.7567/1347-4065/ab26ac/meta