language

- Products

- Processes

- Markets

- News & Events

- About

- Contact

Samco’s deposition processes are renowned for their precision and versatility. We offer:

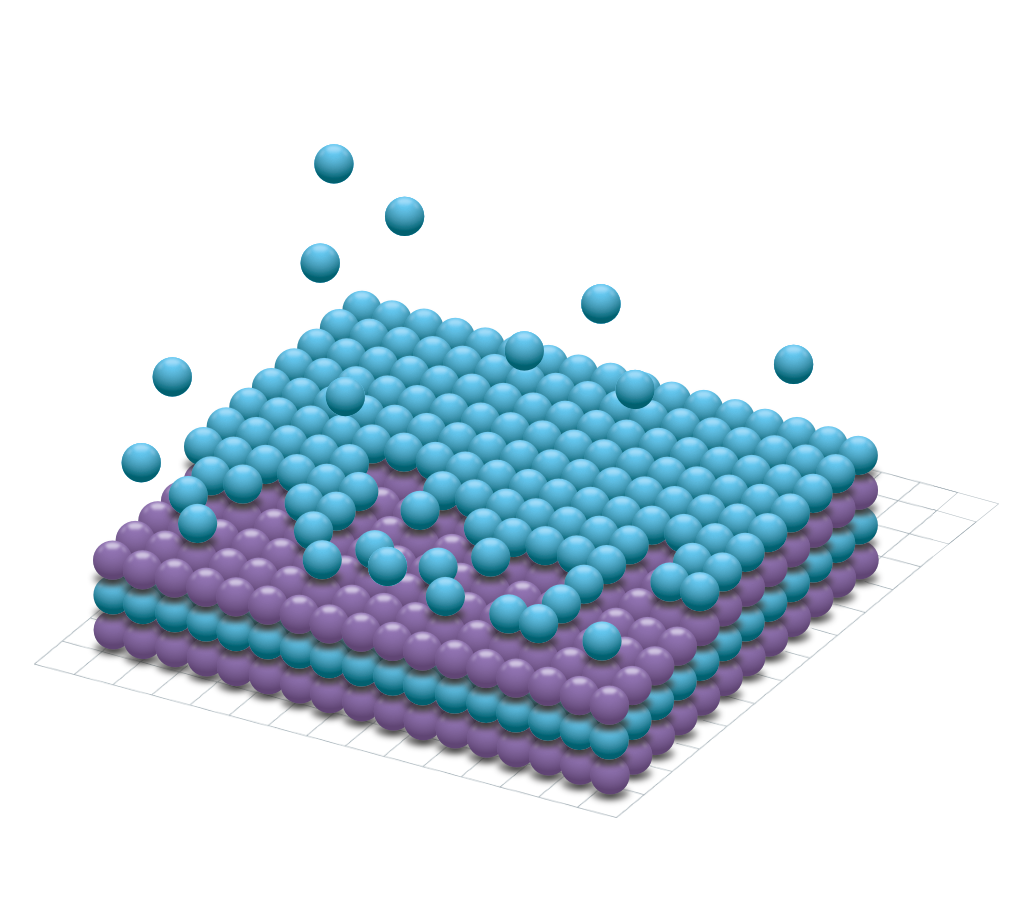

Atomic Layer Deposition (ALD) is a technology to deposit thin films in the atomic scale, using chemical reactions between sample surfaces and precursors in sequential pulsing.

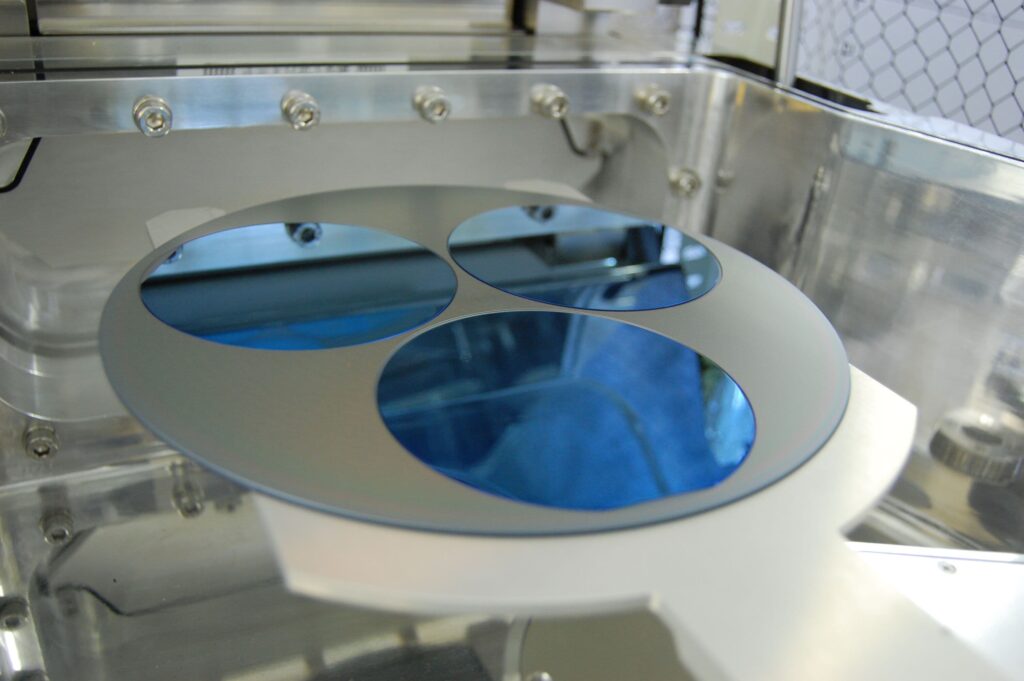

Plasma Enhanced Chemical Vapor Deposition (PECVD) is a widely accepted technique within the industry, to form a thin film by generating active radicals and ions on a target substrate by turning a reactive gas into a plasma state and causing a chemical reaction on the target substrate to be deposited.

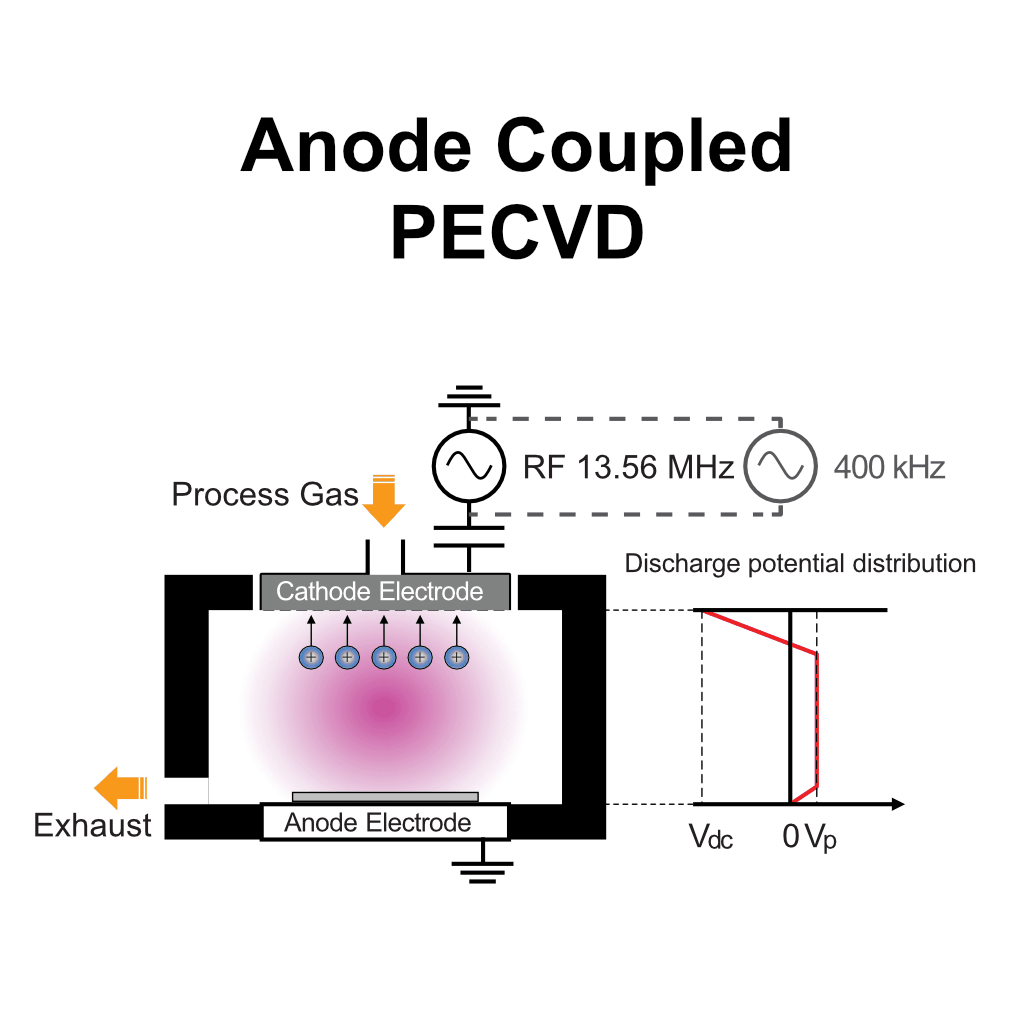

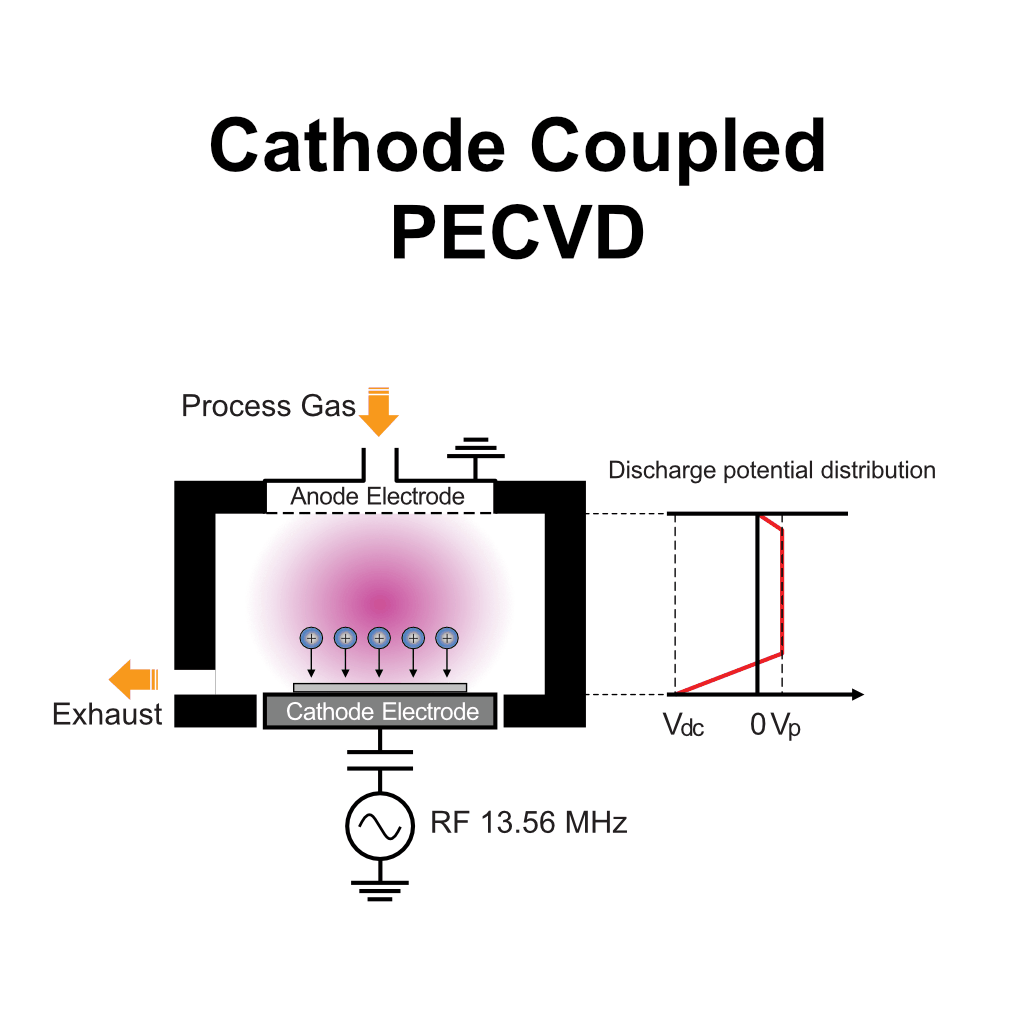

Plasma Enhanced Chemical Vapor Deposition (PECVD) is one of the most fundamental processes in microelectronics fabrication. While most of the PECVD equipment manufacturers provide anode-driven PECVD processes, Samco also offers a unique Cathode PECVD system which provides high-rate deposition with improved step coverage.

Samco’s Liquid Source Chemical Vapor Deposition, LSCVD® technique utilizes a liquid TEOS source to deposit SiO2 films at high speed using a low-temperature process.