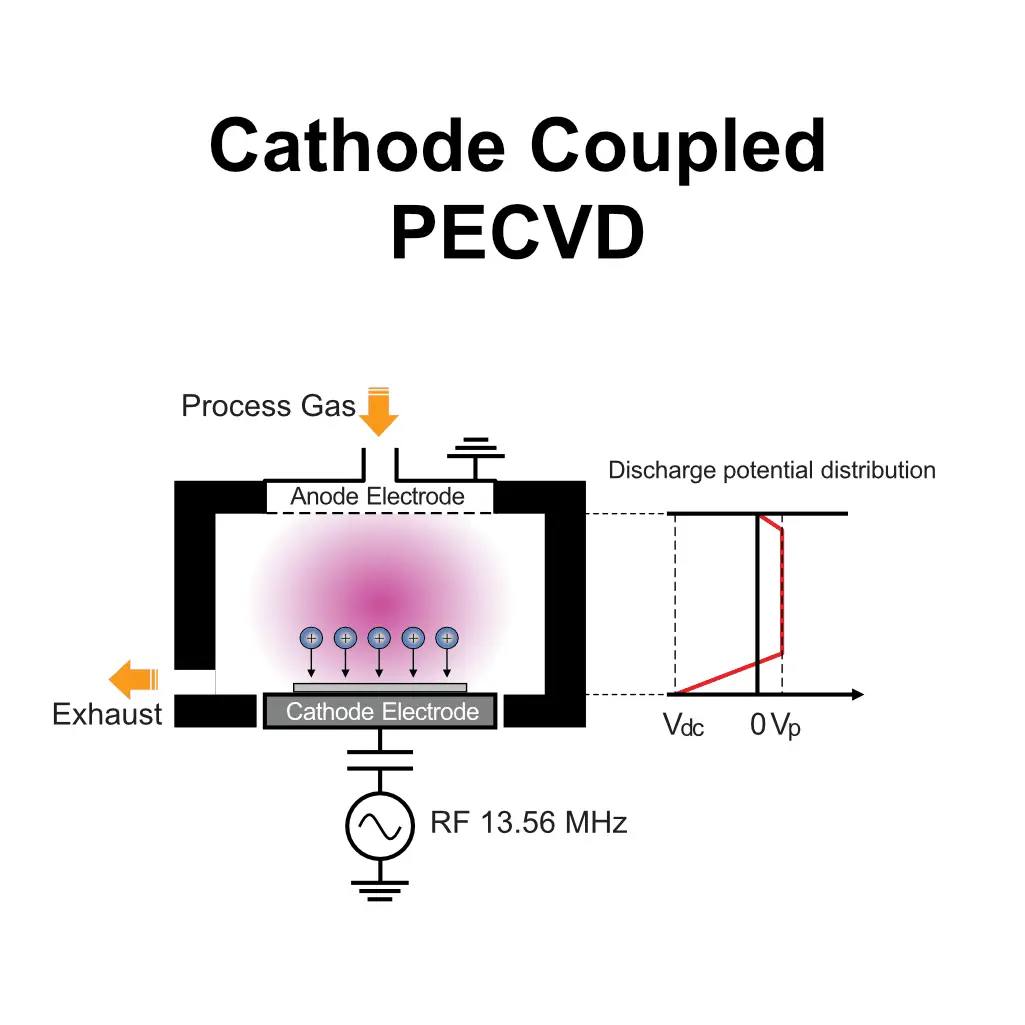

Samco’s Cathode PECVD technology leverages an RF-driven lower electrode to enable high-rate deposition of SiO2 and SiNx films with excellent step coverage and controllable properties. Utilizing proprietary self-bias deposition and a liquid TEOS source, this process achieves deposition rates exceeding 400 nm/min and allows for the formation of thick films over 10 µm with low internal stress. These features make it ideal for advanced applications, including MEMS, TSV, and OLED fabrication, where low-temperature processes (as low as 80°C) are essential. With safer materials and precise control over film characteristics, Samco’s Cathode PECVD provides a versatile solution for both R&D and production environments.

TEOS-SiO₂ deposition

TEOS-SiO₂ deposition through Cathode PECVD offers high deposition rates, low internal stress, and exceptional film uniformity. This process is ideal for applications that require precision and stability, such as optical waveguides, microlens arrays, and insulating layers for advanced device fabrication. Samco’s proprietary deposition techniques ensure superior film characteristics while maintaining compatibility with thermally sensitive substrates.

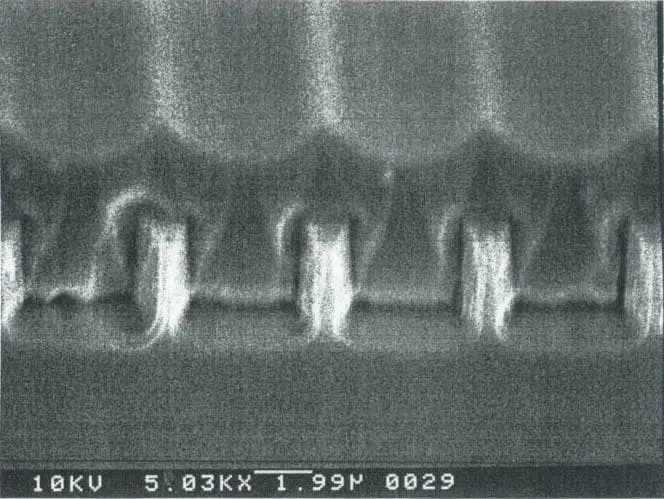

Precise refractive index control for core formation in optical waveguides allows for void-free embedding, even at an aspect ratio of 1, under conditions with high sputtering effects.

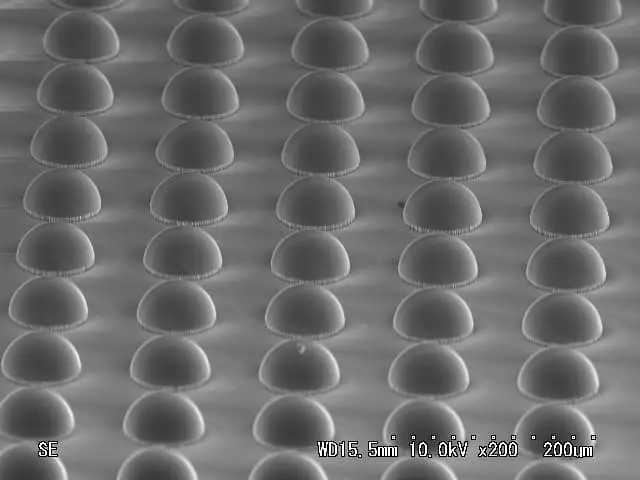

A lens layer of P- and B-doped SiO₂ was dry-etched into a cylindrical form and reflowed at 900–1150°C to form the lens, with curvature controlled by etching conditions, film thickness, and reflow temperature.

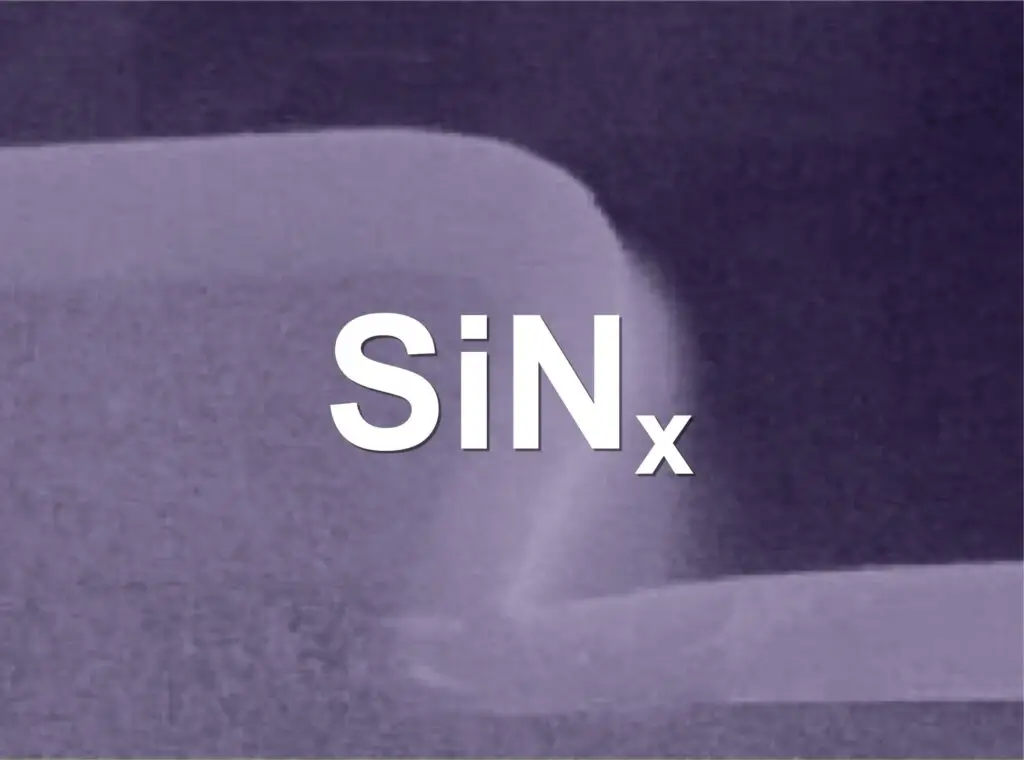

SN-2-SiNx deposition

Samco’s SN-2-SiNx deposition technology enables precise control of refractive index and film properties, making it an excellent choice for advanced optical and electronic devices. This process produces high-quality SiNx films with excellent optical, mechanical, and barrier properties, ideal for use in filters, MEMS devices, and protective coatings. By using the SN-2 liquid source, Samco ensures consistent film quality without carbon contamination, supporting high-performance applications in demanding environments.

A high-Q SiNx ring resonator (Q = 2.4 × 10⁵) with a 100 μm radius was fabricated, featuring ideal refractive index control (1.99) and precise anisotropic etching for improved light extraction efficiency.

Products

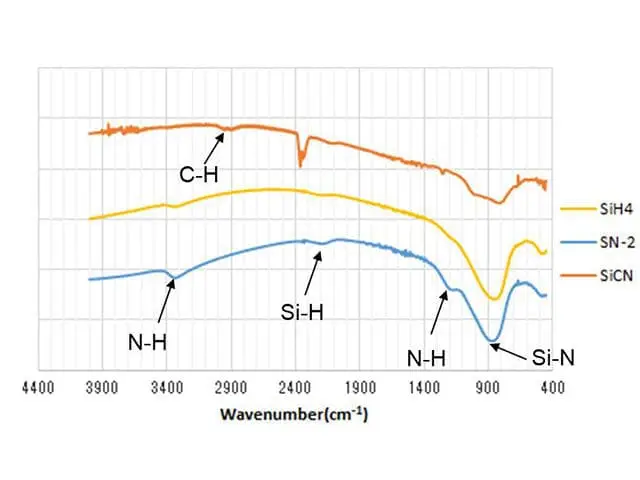

The FTIR waveforms of SN-2-SiNx films show bond peak positions similar to SiH4-SiNx films, with no carbon peaks due to SN-2’s inorganic nature, ensuring comparable film quality.

Products

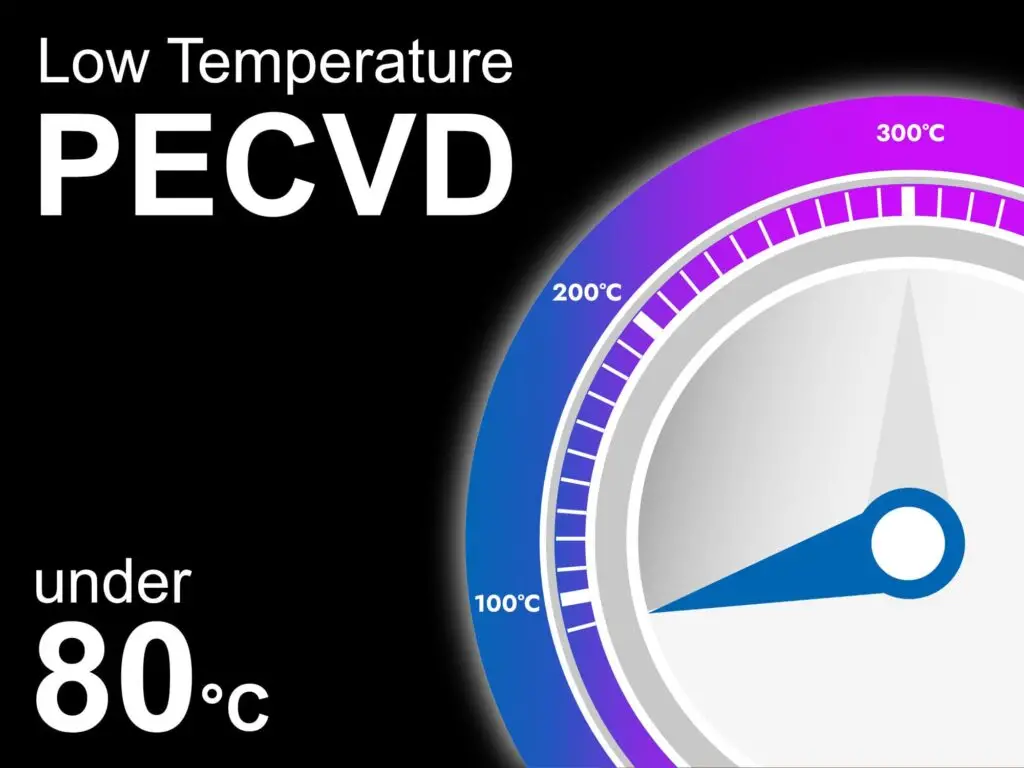

Low-temperature SiO2 and SiNx PECVD capabilities

80°C

& below

Samco’s low-temperature PECVD processes enable deposition of SiO2 and SiNx at temperatures below 80°C, ideal for thermally sensitive substrates used in MEMS, TSV, and OLED applications.

- MEMS: Sacrificial layers and membranes.

- TSV: Oxide passivation with minimal stress.

- OLED: Barrier coatings for flexible substrates.

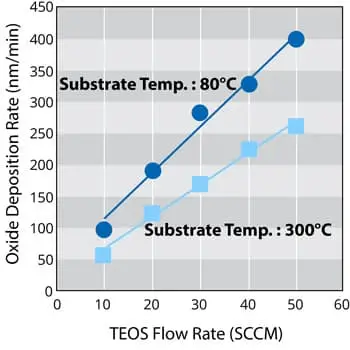

High speed deposition

400

nm/min

Achieve deposition rates exceeding 400 nm/min at 80°C, boosting throughput while maintaining excellent film quality.

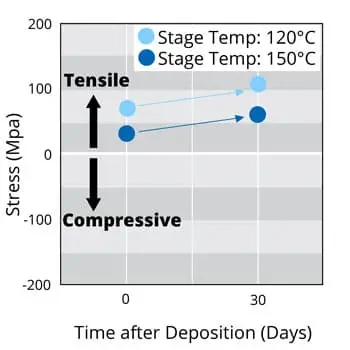

Superior stress control

SiO₂ films deposited at 120–150°C show minimal stress variation even after 30 days, making them ideal for TSV passivation in thinned wafers.

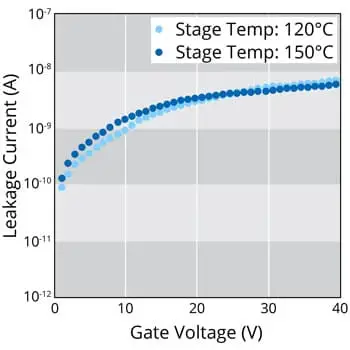

Low current leakage

SiO₂ films deposited at low temperatures demonstrate low leakage (~nA) in deep vias, ensuring reliable passivation.

Optimized optical properties

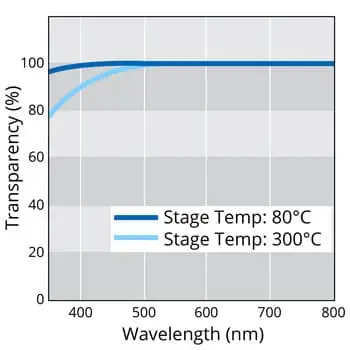

SiNx films deposited at 80°C achieve >90% light transmission in the visible spectrum and <10% reflection, suitable for OLED and solar cell applications.