⌀8″

Cassette Loading

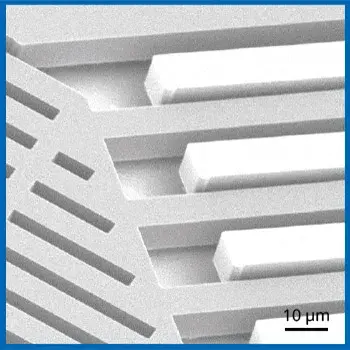

Bosch Process

Vacuum Cassette Chamber

Vacuum cassette loading

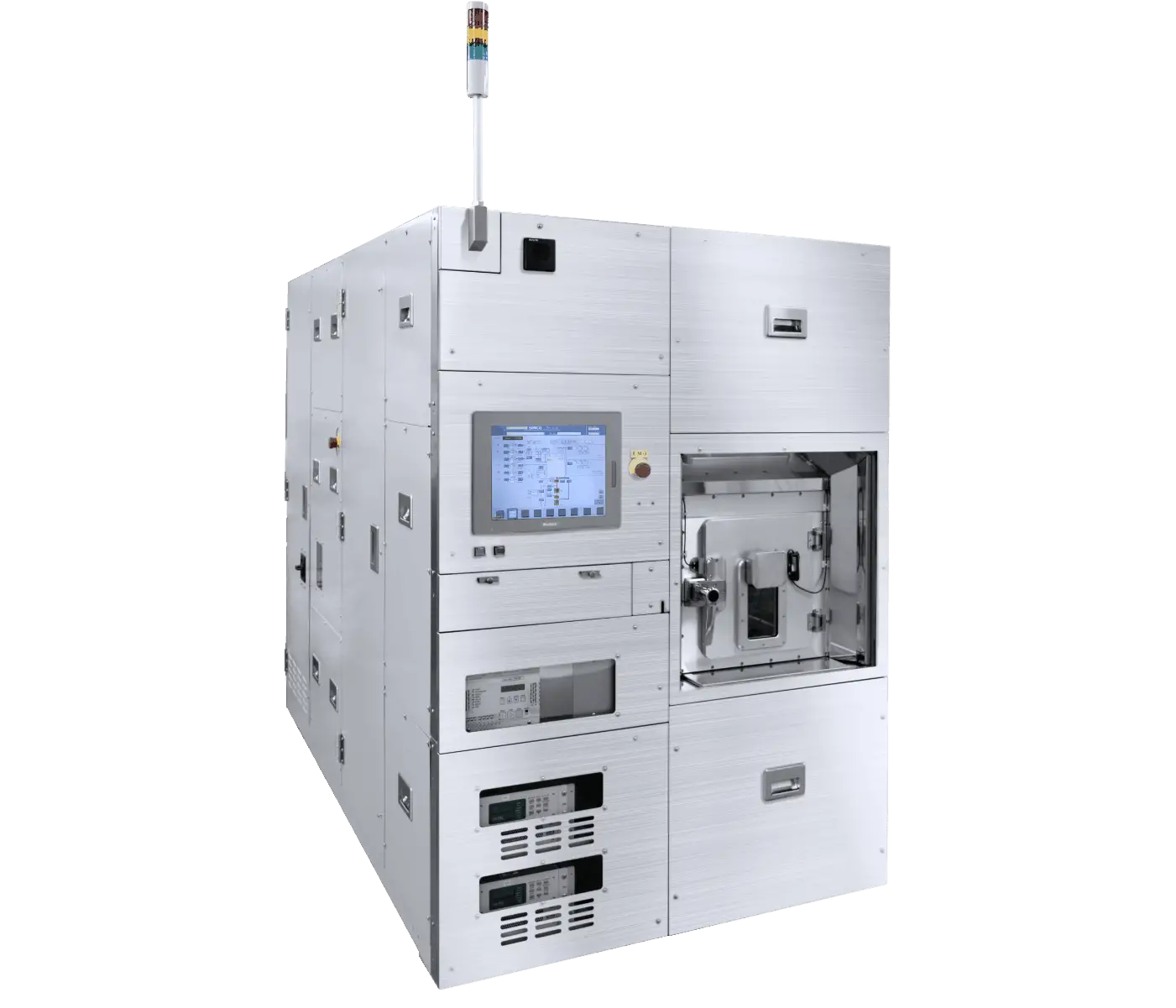

Samco’s RIE-800iPBC is a high performance inductively coupled plasma (ICP) etching system that uses high-density plasma to perform deep silicon etching required by MEMS and TSV applications.

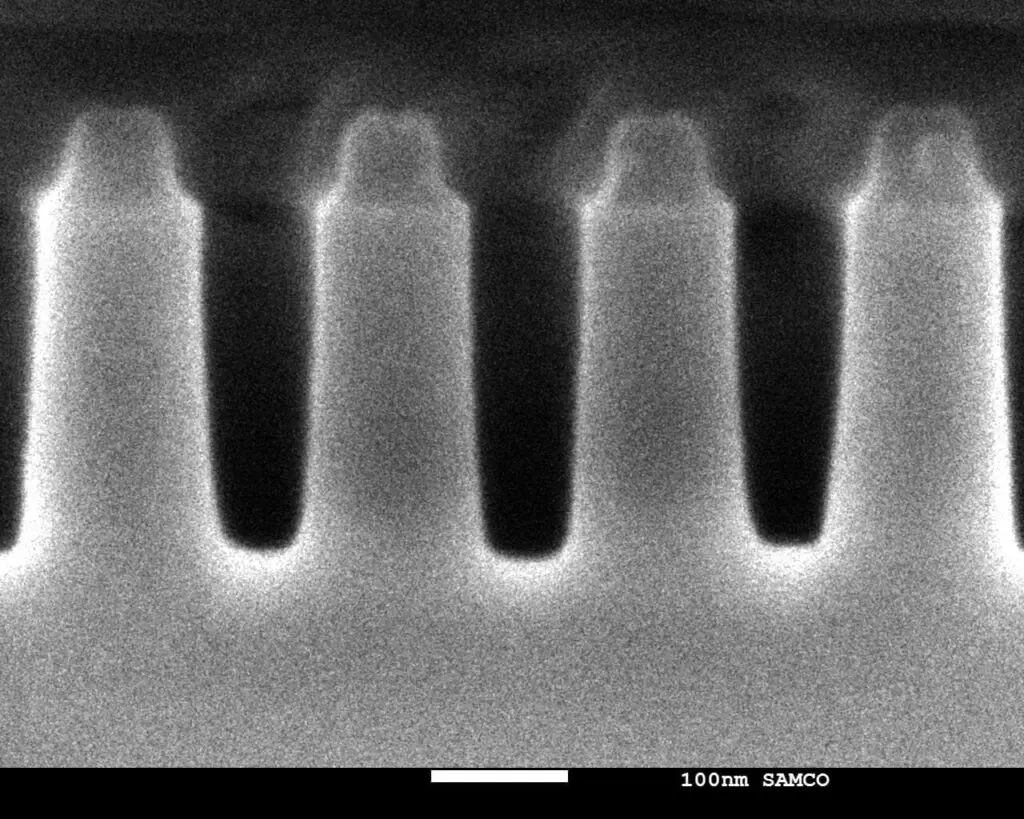

This system is a dedicated silicon etching system specifically designed for the Bosch process (licensed from Robert Bosch GmbH). The systems’ unique reaction chamber, electrode, stage and vacuum design overcomes the problems encountered in competing systems to allow high rate (over 50 μm/min), tilt free, high aspect ratio etching with industry leading selectivity (over 100:1).

Key Features & Benefits

- High rate etching in MEMS mass production

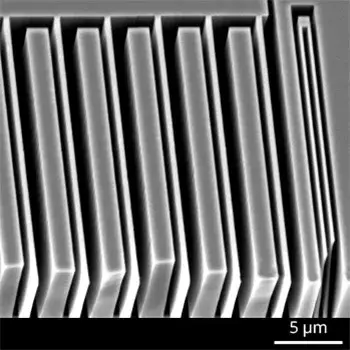

- High aspect ratio etching in mass production

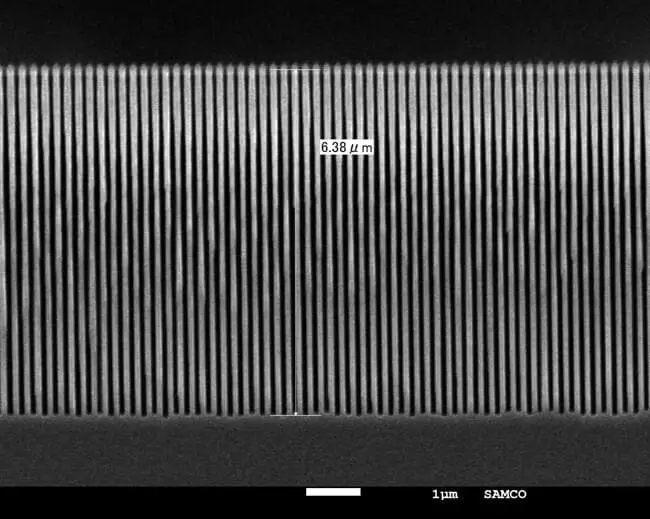

- Control of scalloping / Scallop-less non-bosch process

- Excellent uniformity with tilt control

- Bias pulsing for notch control at silicon on insulator (SOI) wafers

- Extended process library

Applications

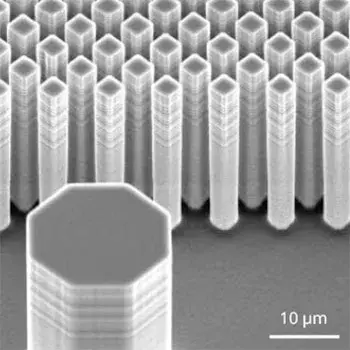

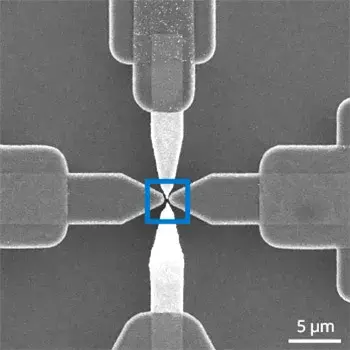

- MEMS (acceleration sensors, gyroscopes, pressure sensors, actuators, etc.)

- Through Silicon Via (TSV)

- Processing of the inkjet printer head

- Power devices (super-junction MOSFETs)

- Plasma Dicing/Scribing