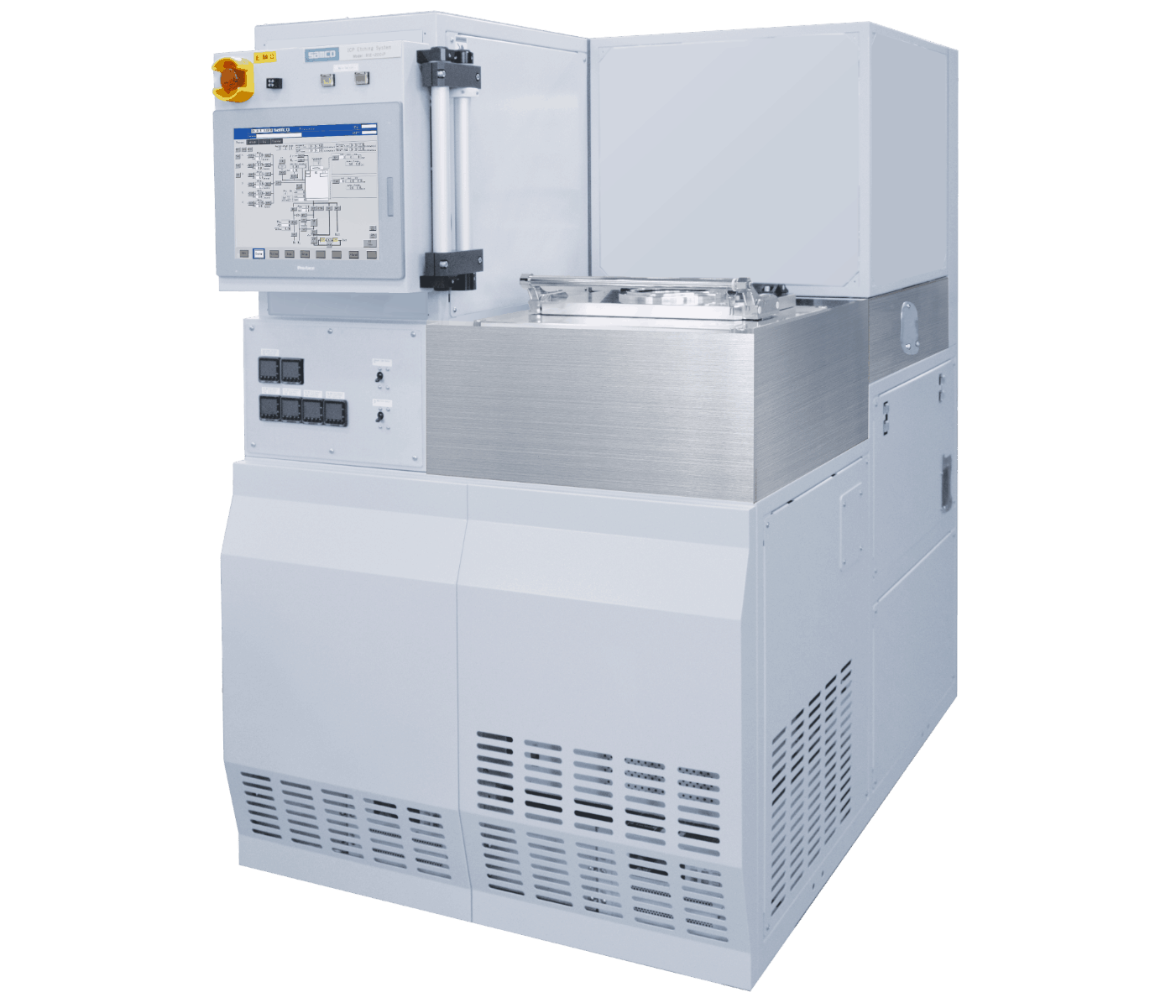

⌀230 mm

Load Lock

Tornado ICP®

Carrier Tray Transfer

Batch processing for small diameter wafers with carrier tray transfer

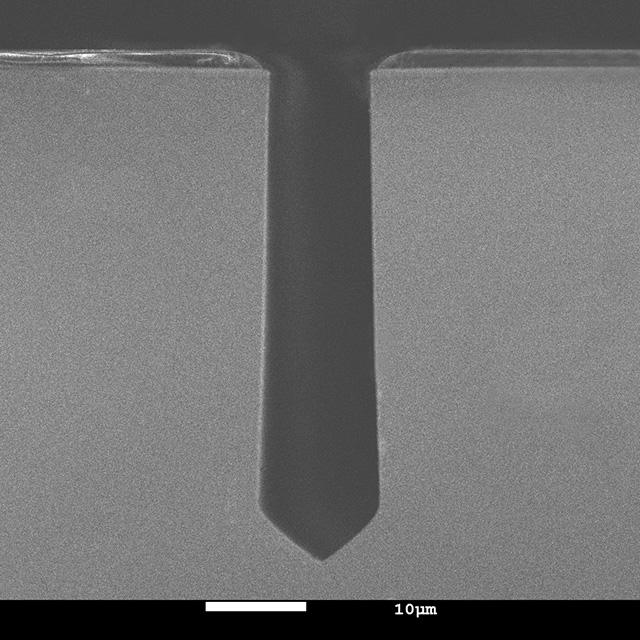

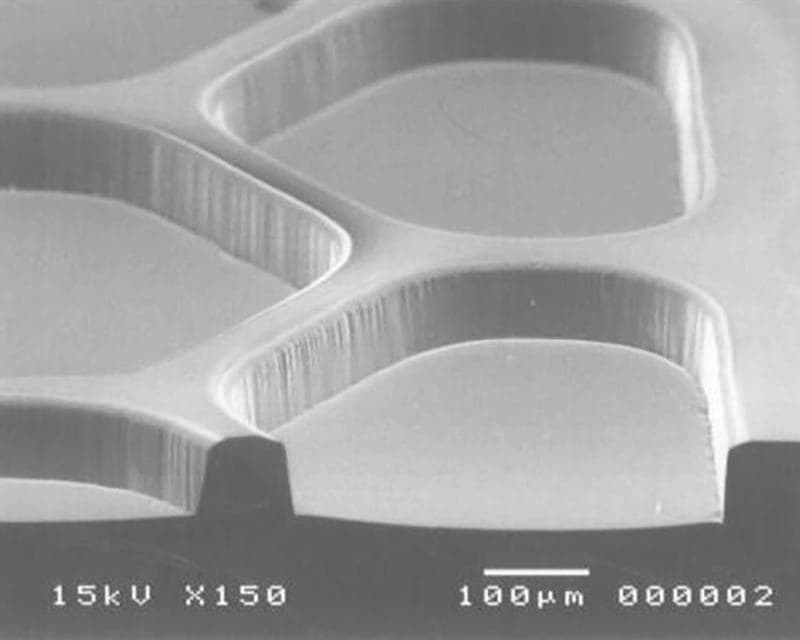

The RIE-230iP is a load-lock ICP plasma etching system that uses an inductively coupled plasma as the discharge to perform ultra-fine processing of various materials at high speed. This system efficiently generates stable, high-density plasma by employing a unique tornado-type coil electrode to enable high-precision anisotropic etching of silicon and various metal thin films and compound semiconductors. In addition, the ø230 mm carrier tray enables simultaneous processing of many compound semiconductors.

Key Features & Benefits

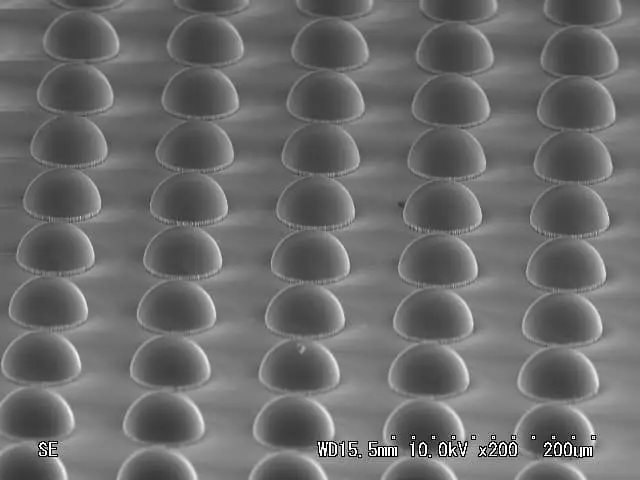

- Processing up to ø230 mm (ø3″ x 5, ø4″ x 3, ø8″ x 1)

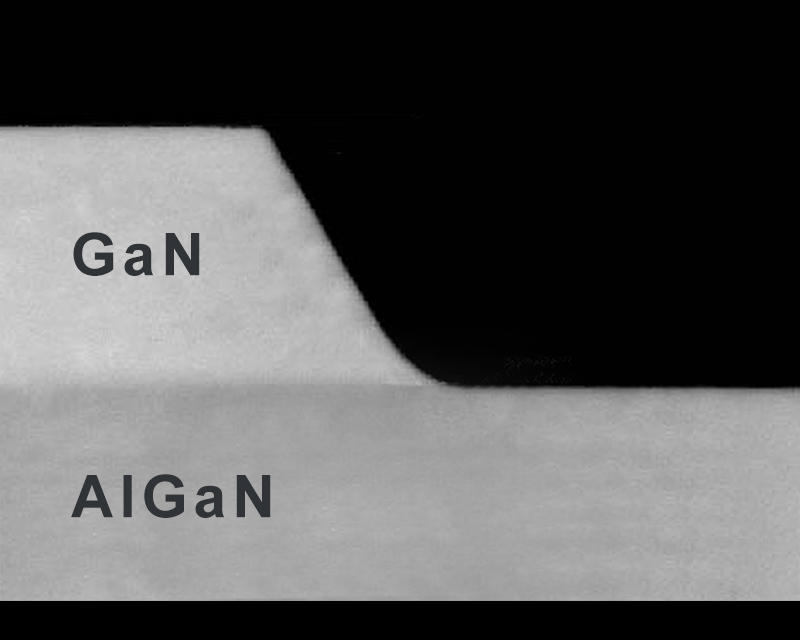

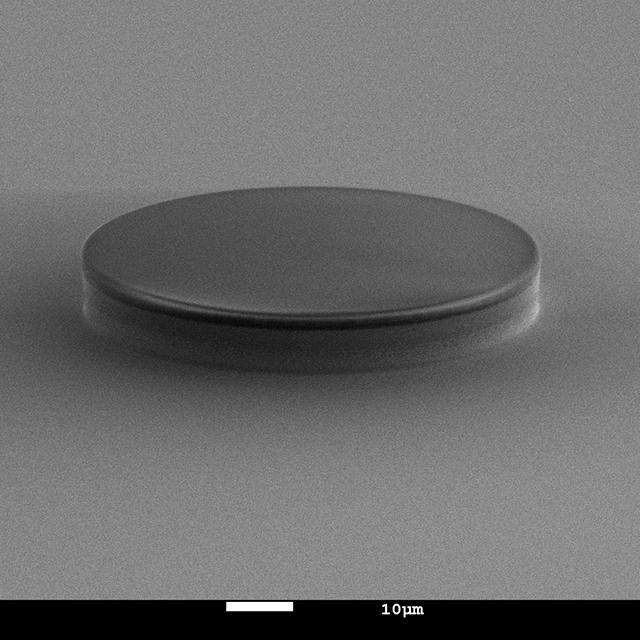

- Samco’s Tornado ICP™ coil can efficiently generate stable, high-density plasma, enabling high selectivity, high accuracy and good uniformity in etching

- A symmetrical evacuation design coupled to a TMP creates an efficient flow

- An optimized gas manifolds to deliver process gas uniformity

- Optional optical/interferometric endpoint detection system enables precise etch depth control over multiple process runs

- ESC and He cooling of the stage and temperature control of the inner side wall of the reaction chamber allow etching under stable conditions

Applications

- High-precision processing of compound semiconductors such as GaN, GaAs, InP, etc.

- Processing of difficult-to-etch materials such as ferroelectrics and electrode materials.