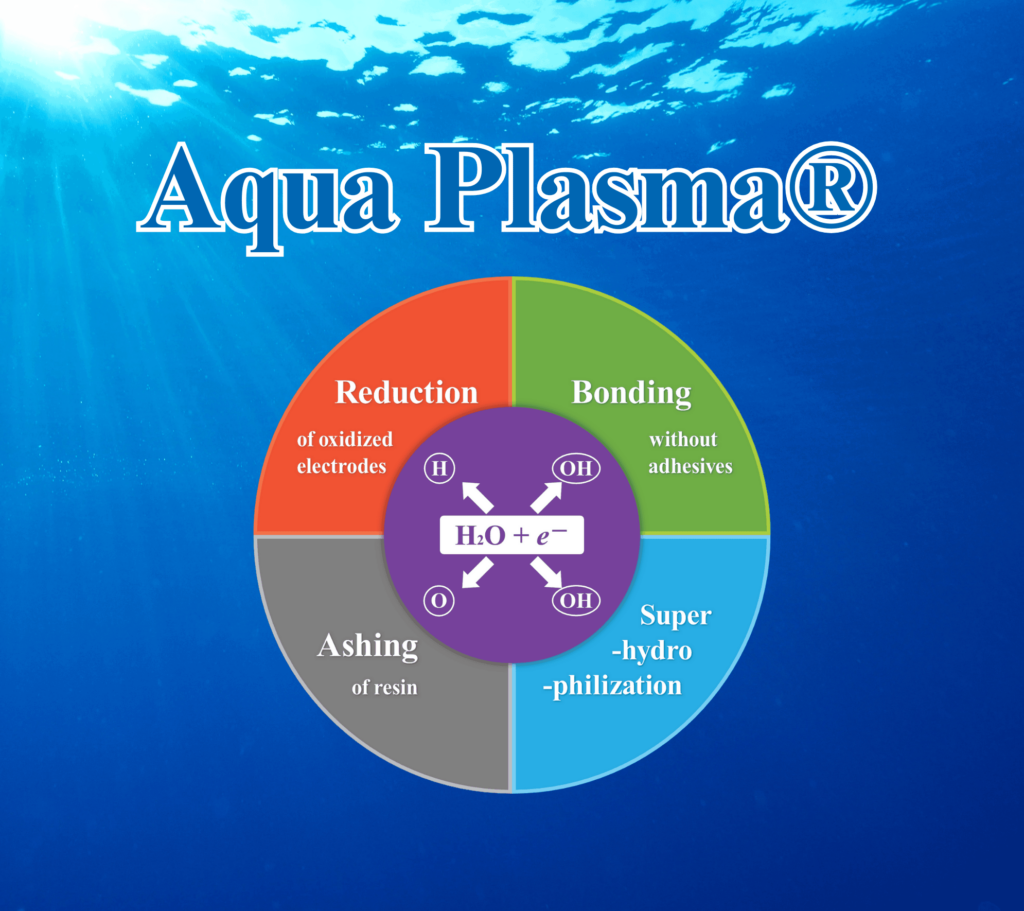

Samco’s Aqua Plasma® technology provides an advanced, water vapor-based surface treatment solution for a wide range of materials, including silicon, glass, metals, and polymers. It enhances surface wettability by creating hydrophilic surfaces, improving adhesion for applications like microfluidic device fabrication and robust polymer-to-polymer or polymer-to-glass bonding. Aqua Plasma effectively supports complex 3D structures, such as the inner surfaces of tubes, while preserving the material properties of sensitive substrates like COP, essential for optical applications. Additionally, it cleans oxidation layers from copper and silver surfaces without causing further oxidation or particle redeposition, making it ideal for microelectronics packaging.

Reduction

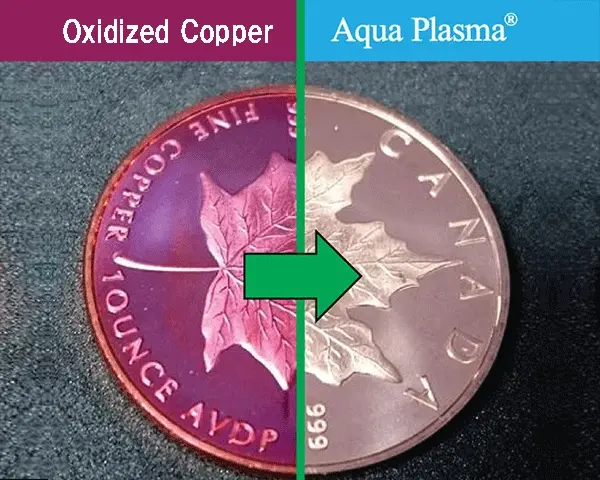

Aqua Plasma® provides a safe and efficient method for cleaning oxidized metal surfaces such as copper, silver, and gold, essential in microelectronics packaging. Unlike conventional O₂ or Ar plasma treatments that risk oxidation or particle redeposition, Aqua Plasma removes oxidation layers without altering surface properties, preserving brightness and integrity. Its H₂O-based approach eliminates safety concerns associated with H₂ plasma, offering a non-destructive solution ideal for advanced applications like electrode preparation and device packaging.

Copper, valued for its electrical and thermal properties, oxidizes easily, leading to issues like increased resistance and poor contact in wiring. Aqua Plasma® effectively reduces copper oxide without causing further oxidation, restoring oxidized surfaces to their original copper color.

Silver, valued for its electrical and optical properties in LED packages, oxidizes under conventional oxygen plasma cleaning, causing discoloration. Aqua Plasma® effectively removes silver oxide without further oxidation, restoring the original silver color and maintaining its reflective quality.

Surface modification

Aqua Plasma® enables precise surface modification of materials such as silicon, glass, metals, and polymers, improving wettability and adhesion. Plasma-treated PMMA samples demonstrated hydrophilic surfaces, enhancing bonding with materials like PDMS, commonly used in microfluidic device fabrication. Aqua Plasma’s low-impact process preserves the optical properties of sensitive materials like Cyclic Olefin Polymer (COP) and is suitable for intricate 3D structures, including the inner walls of tubes.

Aqua Plasma® surface modification enables room-temperature bonding of cyclic olefin polymers (COPs) with a bond strength exceeding 160 N/cm², making it ideal for fabricating microfluidic devices with low-background fluorescence requirements.

Aqua Plasma® treatment enhances the hydrophilicity of cyclic olefin polymers (COPs), achieving lower water contact angles compared to oxygen plasma and supporting their application in fluorescence detection microfluidic devices.