⌀8″

Open Load

none

none

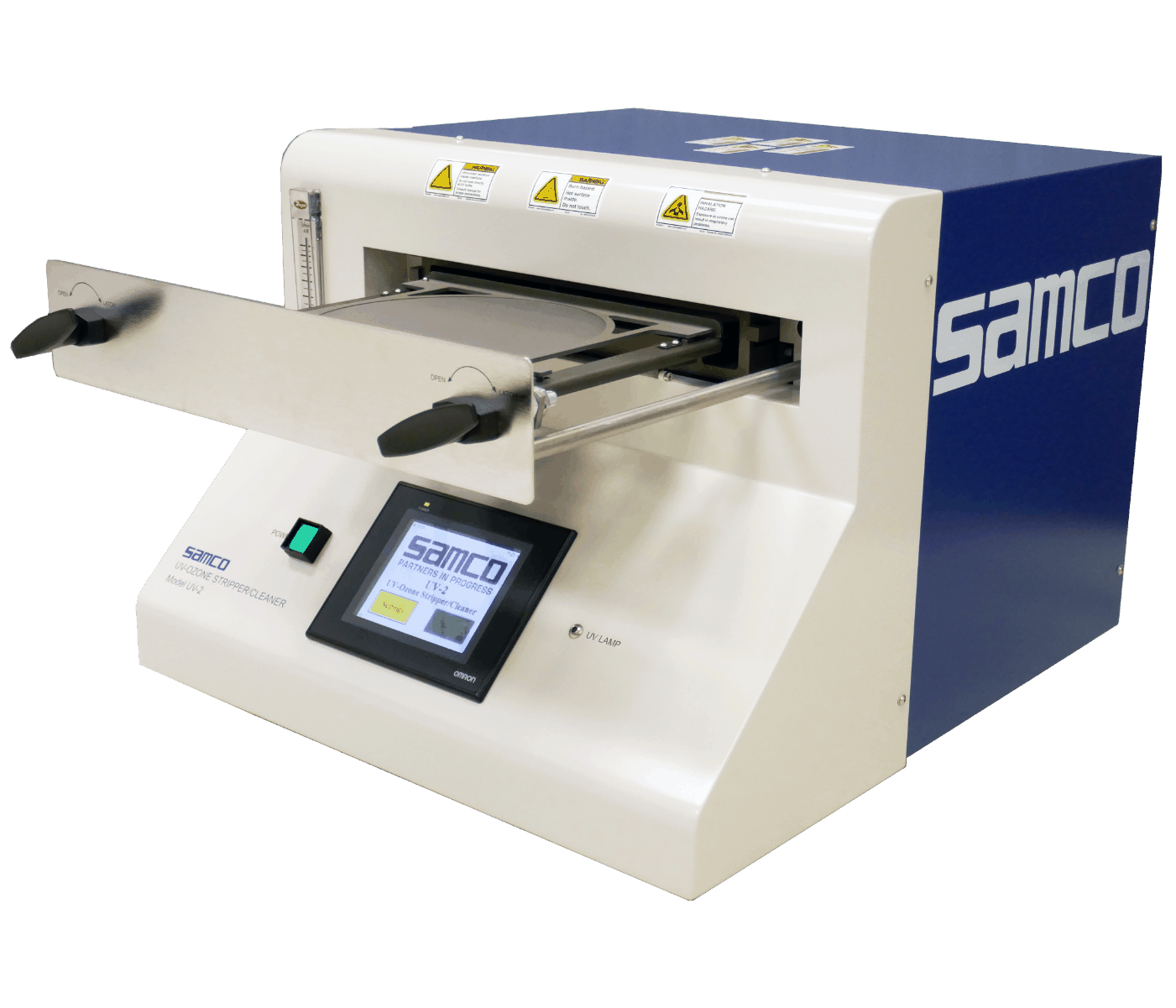

Compact power for up to 8-inches

The UV-2 is a versatile, compact benchtop UV ozone cleaning system designed for R&D and low-volume production. Leveraging a unique combination of ultraviolet radiation, ozone, and heat, it effectively removes organic materials from a wide range of substrates, including silicon, gallium arsenide (GaAs), sapphire, ceramics, and glass. Its advanced design ensures uniform cleaning, surface modification, and UV curing without the need for a vacuum system. Ideal for labs and production environments, the UV-2 offers precision cleaning in a space-saving package.

Key Features & Benefits

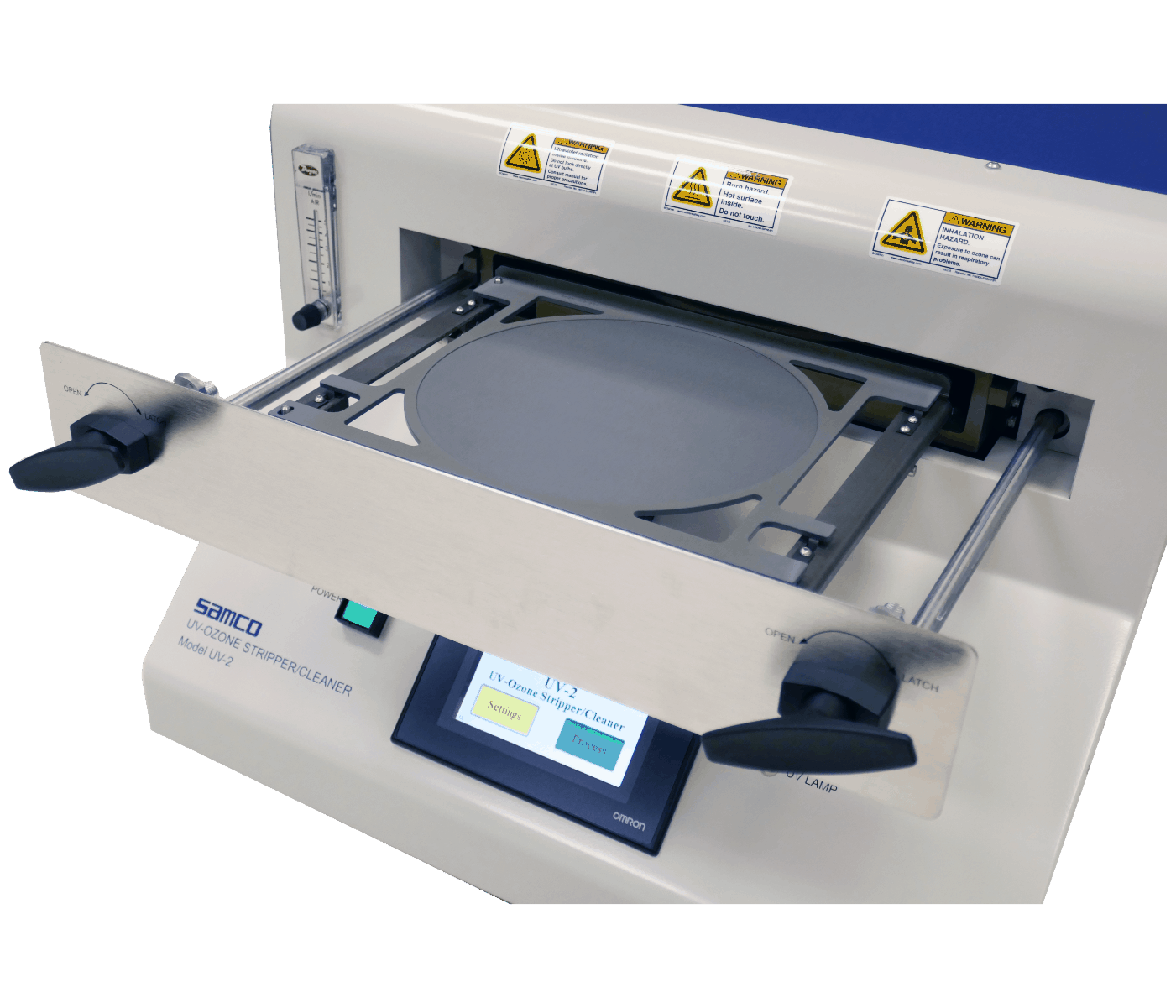

- Processes up to 8-inch wafers

Supports various sample shapes and sizes. - Compact design

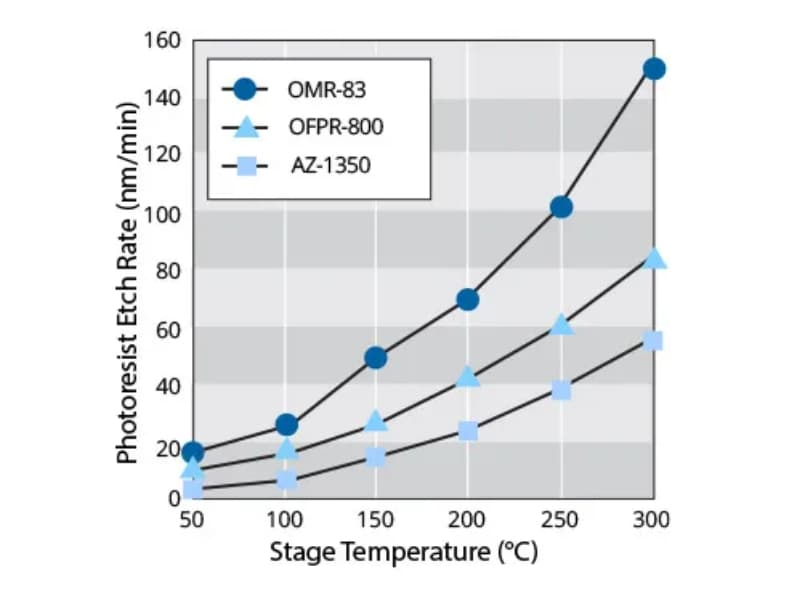

Minimizes benchtop space requirements. - Heated sample stage

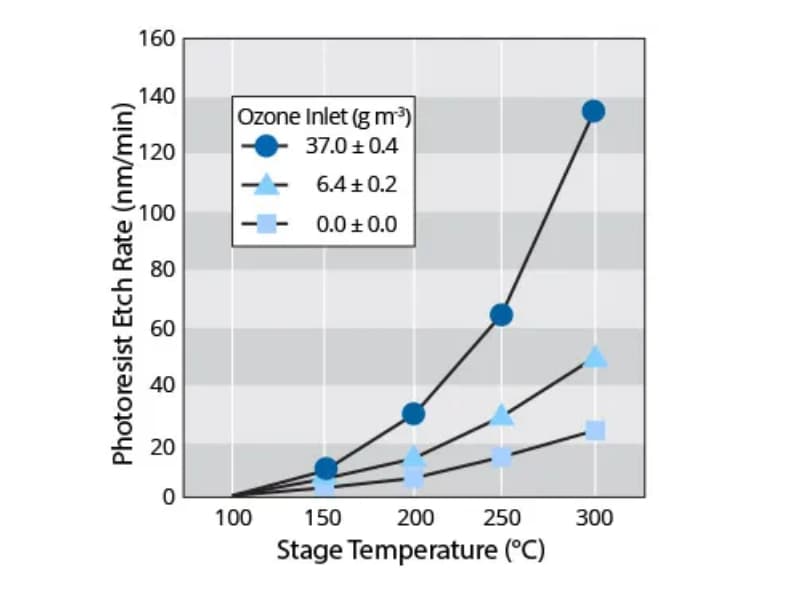

Accelerates cleaning and enables a broad process temperature range (ambient to 300°C). - Atmospheric pressure operation

No need for vacuum systems. - Dry, gentle process

Prevents electrical damage and preserves delicate substrates. - Drawer interlock system

Ensures safe operation by disabling the system when open. - Automated nitrogen purge system

Purges the chamber after each process run. - Built-in ozone catalyst

Reduces ozone emissions for safe operation. - Sealed process chamber

Prevents contamination from ambient air.

Applications

- Organic contamination removal

- Pre-cleaning wafers before deposition (e.g., GaAs prior to MBE, sapphire prior to HgCdTe)

- Photoresist descumming and polyimide stripping

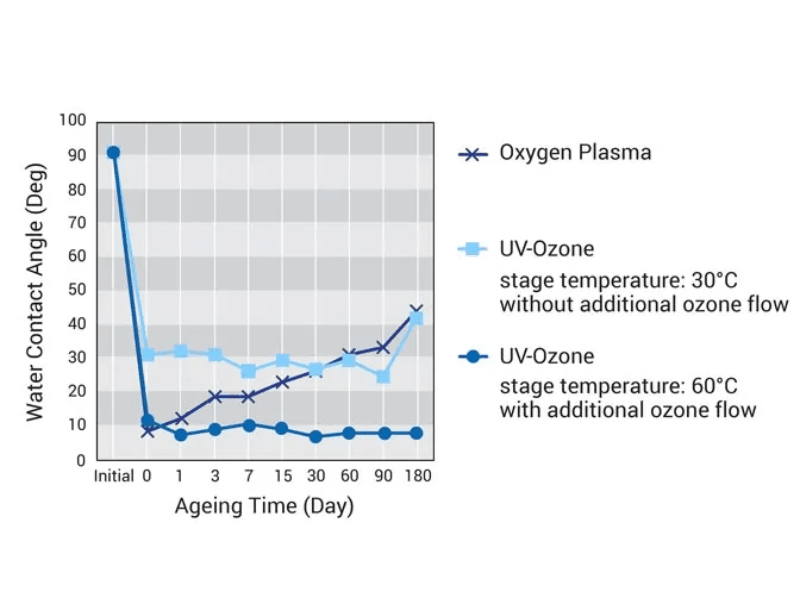

- Surface modification for improved adhesion

- Final cleaning before wafer bonding

- UV curing

- Growth of thin, stable oxide films (e.g., Ge, Si)

- Cleaning precision tools like AFM tips