⌀4″

Open Load

none

none

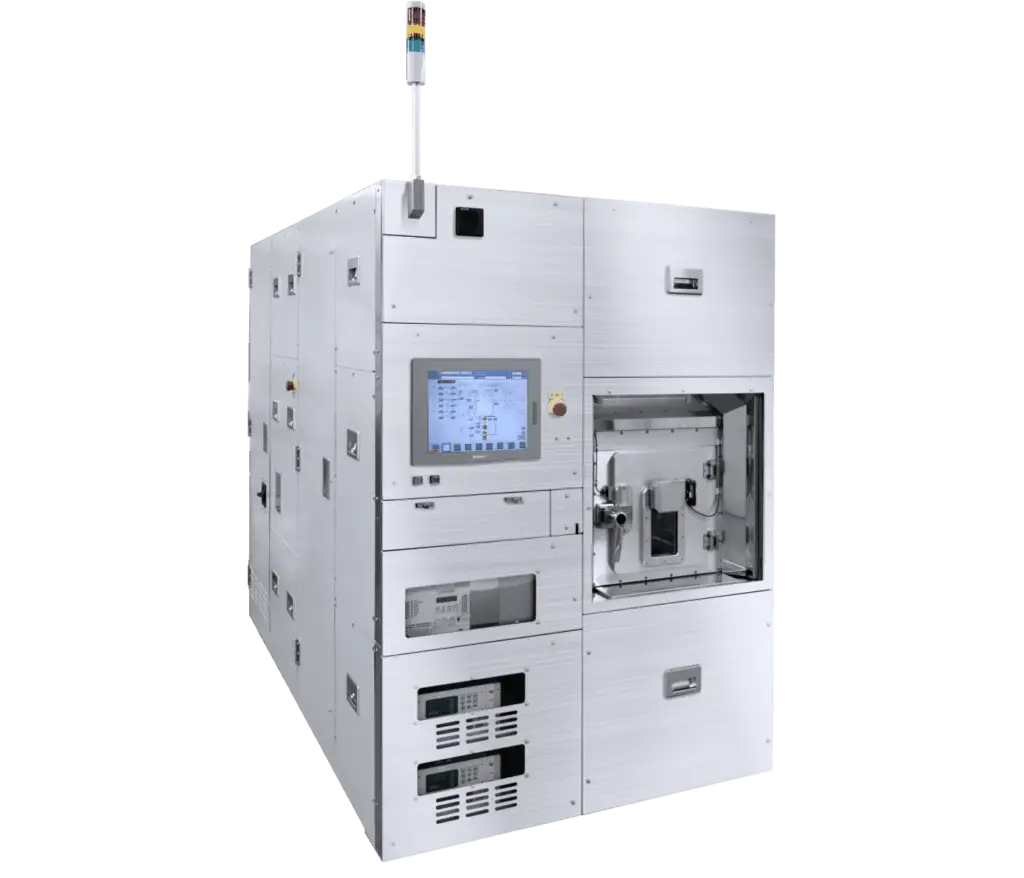

Compact benchtop system

The VPE-4F is an XeF₂ etching system tailored for etching silicon sacrificial layers in MEMS (Micro-Electro-Mechanical Systems) fabrication. Its dry etching process eliminates stiction issues associated with wet processing, streamlining production by removing the need for pretreatment and post-processing. Designed for efficiency and space-saving, the VPE-4F offers a reliable solution in a compact, tabletop form factor.

Key Features & Benefits

- Non-damaging dry process

Operates without plasma, preventing device damage from electric fields caused by electron or ion impacts. - Precise etching rate control

Intermittent gas flow enables easy adjustment of etching speed and optimized gas usage. - Compact and cost-effective

Desktop design minimizes installation space while delivering high cost performance as a dedicated machine.

Applications

- Etching of silicon sacrificial layers in MEMS fabrication.