Novel low-cost system for R&D

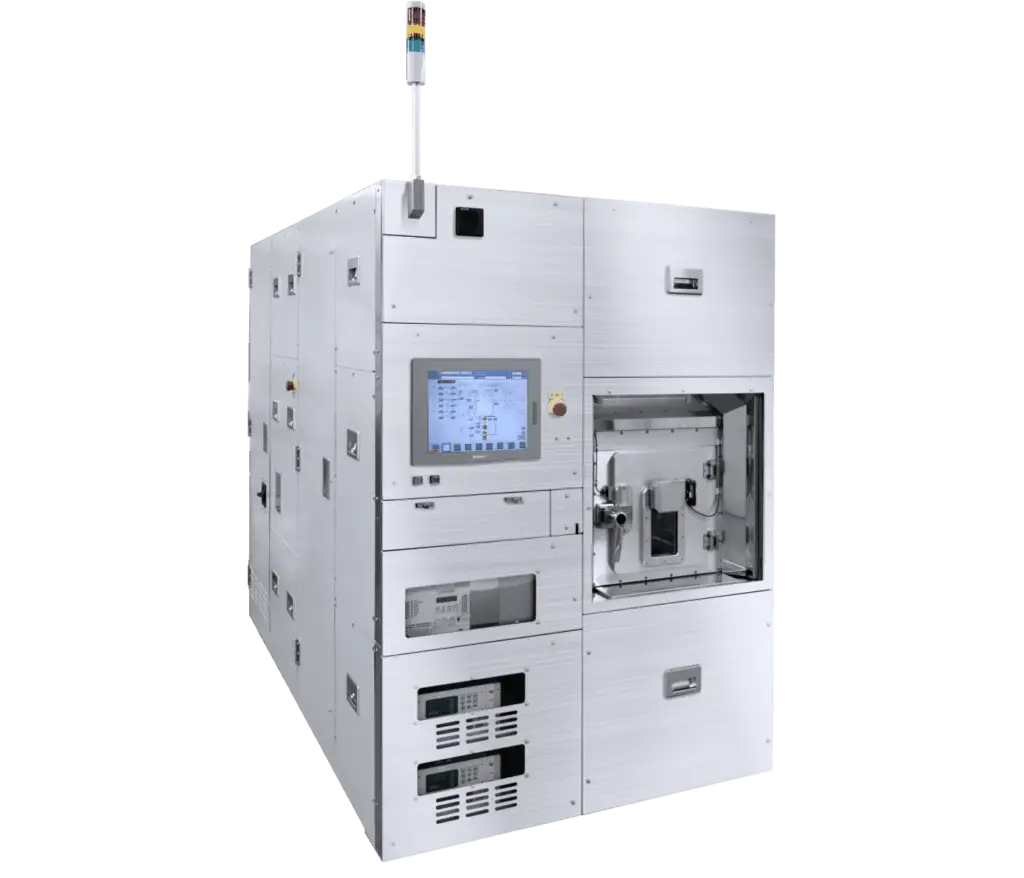

The RIE-400iPB is a load lock deep silicon etching system specifically designed for the Bosch Process, accommodating wafers up to 100 mm (4 inches). The system is equipped with a unique reaction chamber, a temperature-controlled electrode, and a high-flow exhaust system, all integrated into a compact, space-saving design. This design ensures reliable and exceptional process control, enabling high-rate, high-aspect, tilt-free etching with excellent selectivity. Additionally, the system can achieve high-rate SiO2 etching by substituting the ICP source.

Key Features & Benefits

Bosch Process Optimized ICP�Source

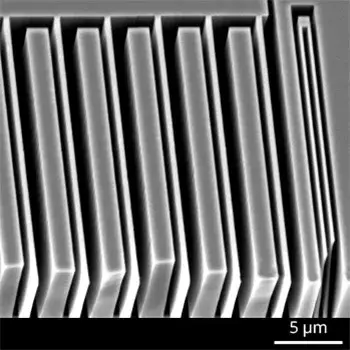

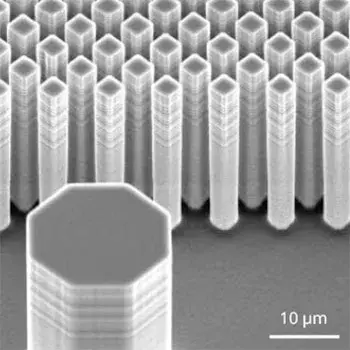

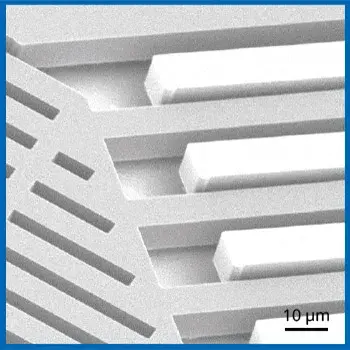

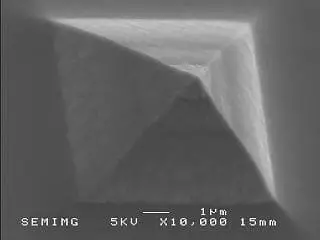

- High rate Si etch (>14 µm/min)

- Leading PR:Si selectivity (up to 250:1)

- Etch up to 400 µm deep

Bosch�Process Optimized RF and Gas Systems

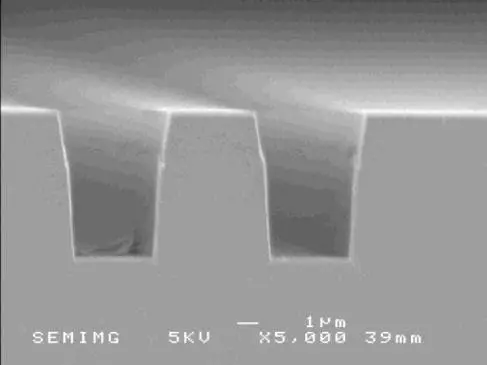

- Stable and repeatable plasma discharge during gas switching

- Reduction of scallop size whilst maintaining etch rates

- Notch prevention technology for SOI etch

Stable�Repeatable Processing

- Chamber heating for improved process stability

- ESC for stable wafer temperatures throughout the process

High Performance SiO2 Etch (Option)

- Quick change to specialized SiO2 etch mode

- Up to 600 nm/min etching rates with minimal polymer formation

Easy�System Maintenance

Applications

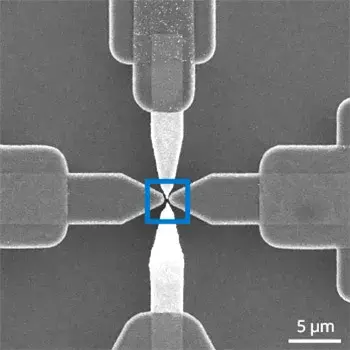

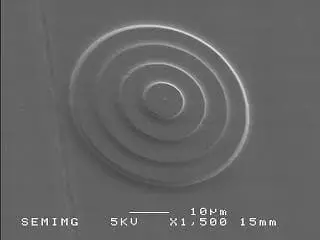

- MEMS

- Accelerator

- Gyroscopes

- Pressure sensors

- Actuators

- Medical devices such as μTAS

Options

- SiO2 etch ICP unit

Processes

Papers

http://dx.doi.org/10.3390/proceedings1040394