Introduction to the Long-Term Process Stability of Samco Plasma CVD “PD-220 Series” Systems

Samco Inc.

Introduction

Samco Inc. boasts a 45-year history of experience in developing plasma CVD process technology and supplying products, establishing itself as a leader in the industry. In recent years, production plasma CVD systems have been increasingly adopted in the fields of compound semiconductors and electrical components. This technical report presents data on the long-term process stability of the reaction chamber of our flagship PD-220 Series CVD systems.

System Introduction

The PD-220 Series offers a wide range of options suitable for both research and production applications. These include deposition using SiH4 gas and liquid TEOS, dual frequency superposition of 13.56 MHz and 400 kHz, and deposition at frequencies of 27, 40, and 60 MHz. The reaction chamber supports stable plasma generation through a plasma confinement mechanism and adjustable electrode spacing, enabling extended use with only dry cleaning. The long-term process stability data provided here reflects SiN deposition at 13.56 MHz using the PD-2202LC system, which is equipped with a vacuum cassette chamber and two reaction chambers.

Long-Term Process Stability Data (without opening the reaction chamber for maintenance)

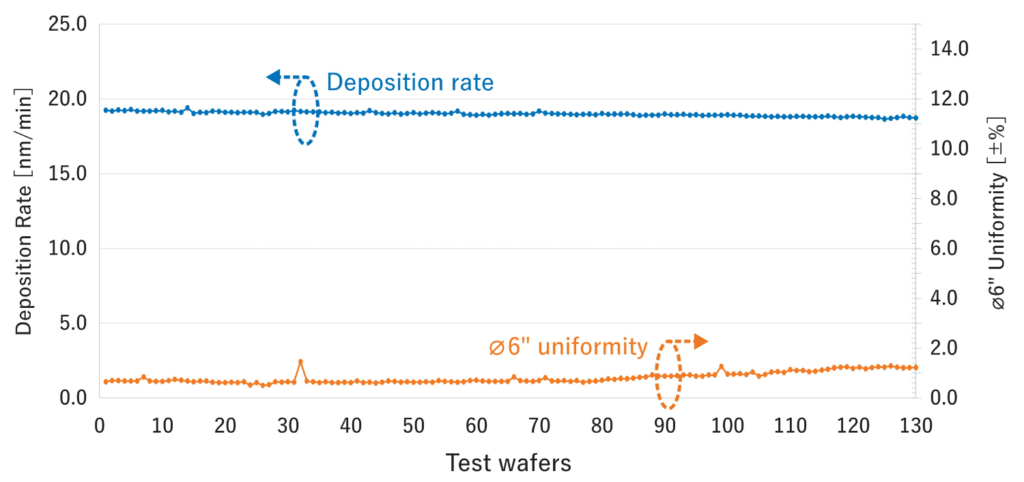

This data reflects the test wafer deposition measurements taken after dry cleaning and pre-coating. A total of 130 measurements were conducted over 6 months, with intervals of 1 to 3 days. Dry cleaning was performed once the film thickness reached 20μm, which typically requires 80 to 90 deposition cycles, spanning 1 to 3 days. Only one of the two chambers in the PD-2202LC was utilized.

Figure 1 illustrates the long-term process stability data of SiN deposition using the plasma CVD system PD-2202LC. The deposition rate and film thickness uniformity were measured on 6-inch test wafers for process verification in a production setting. Over 6 months, the system maintained a highly stable uniformity of ±2% or less, with a consistent deposition rate of 20nm/min.

Conclusion

This report has presented the long-term process stability results of SiN deposition using the plasma CVD system PD-220 Series “PD-2202LC” (Figure 2). Reducing the frequency of maintenance cycles, including component replacement and wiping, which exposes the reaction chamber to external air, has proven effective in minimizing downtime, decreasing maintenance efforts, and controlling moisture levels within the chamber. We are confident that the PD-220 series will gain wide acceptance as a production system for both compound semiconductors and electrical components, thereby enhancing our market presence in production systems.